Koryx Announces Updated PEA Results for the Haib Copper Project, Southern Namibia

92,000MT ANNUAL PAYABLE CU PRODUCTION (1st 10 Years)

$1.81/lb C1 COST and $2.05/lb AISC (1st 10 Years)

US$1.351bn AFTER-TAX NPV8%

20.1% AFTER-TAX IRR

23 YEAR MINE LIFE

The Haib project is a simple, scalable, advanced-stage, open pit sulphide Cu/Mo project located at low altitude in an ideal, infrastructure-rich area of southern Namibia close to the South African border. It was formerly owned by Rio Tinto and Teck, and since the end of 2024 is under credible, new Namibian leadership & management with (i) the stated aim of optimizing, right-sizing and de-risking the project towards an investment decision and/or asset/equity sale, and (ii) a fifteen (15) year track record of successful Namibian mine development and project exits.

The preliminary economic assessment (“PEA”) objective is to reset the project scope & reposition Haib as a credible, large-scale, long-life, low-risk and low-cost open pit milling & flotation mine plus supplemental heap leach production. The PEA is based on the 2024 Mineral Resource Estimate (“MRE”) block model that was used to report the 31 August 2024 MRE, with none of the drilling since then included in this PEA. All additional drilling and extensive geological re-modelling will be reflected in an updated MRE and technical study to be published in the second half 2026.

Significant further upside to be unlocked through ongoing drilling (potential size and grade improvements) and metallurgical and sorting testwork (scalability and potential cost reductions) which will be reflected in the next technical study.

PEA Highlights

- NPV8% of US$1.351bn (after-tax) and US$2.358bn (pre-tax) at LT analyst consensus Cu price of US$4.31/lb and realistic technical assumptions.

- US$1.559bn (incl. 10% contingency) upfront construction capital.

- US$543m LOM sustaining capital (including US$149m in HL construction capital in year 1 and 2 of production).

- 20.1% IRR (post-tax) and 25.2% IRR (pre-tax) with 3.9 year payback.

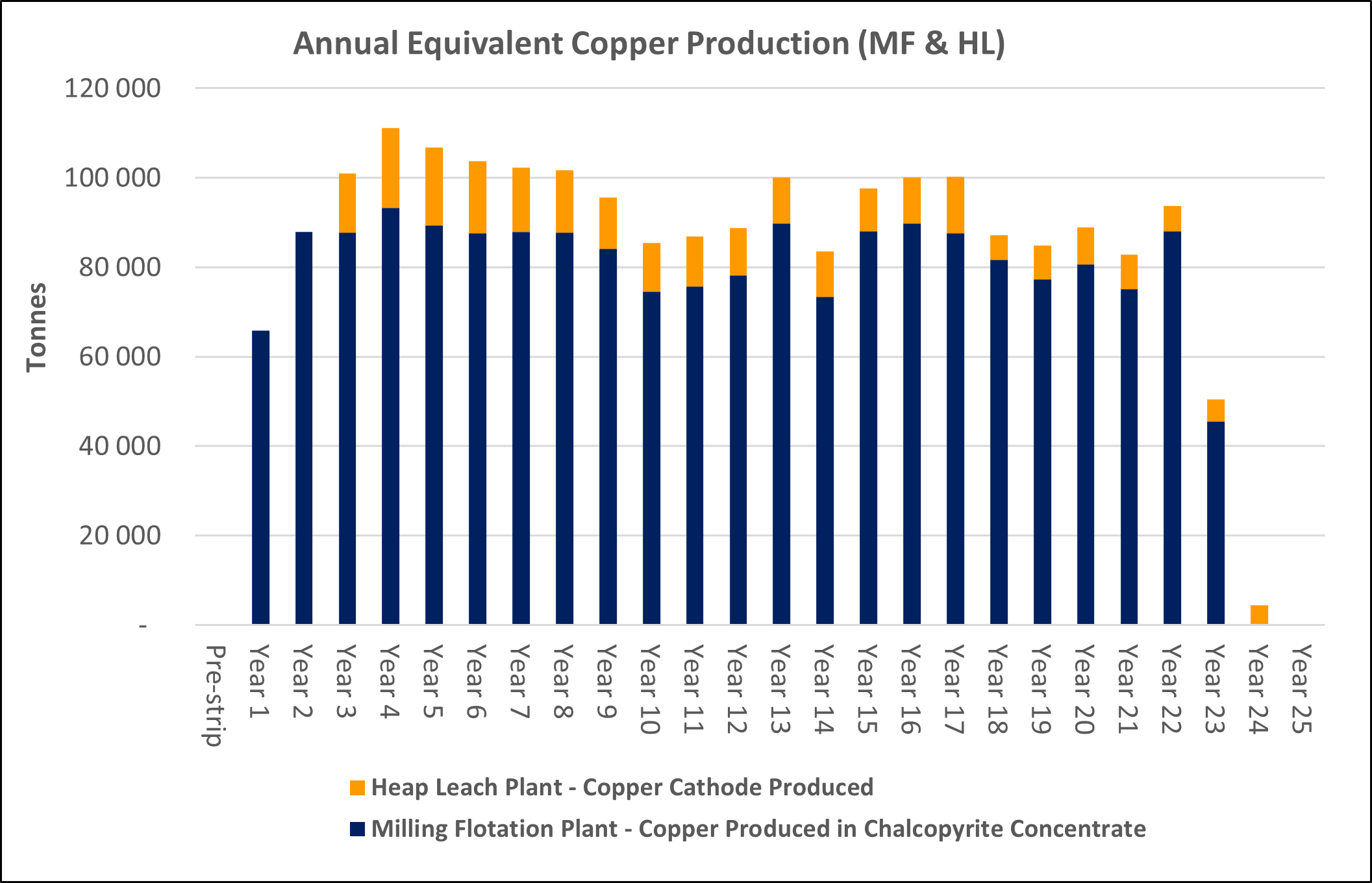

- 23 years Life of Mine with 92ktpa of annual payable Cu production (Average Years 1-10)

- US$1.81/lb C1 cash costs and US$2.05/lb AISC (Average Years 1 – 10).

- US$2.21/lb C1 cash costs and US$2.47/lb AISC (Average Life-of-Mine).

- Capital intensity of US$16,871/t of annual payable Cu production (Average Years 1 – 10).

- Capital intensity of US$17,702/t of annual payable Cu production (Average Life-of-Mine).

-

Production of Cu/Mo concentrate via a 28mtpa conventional crushing/milling/flotation (MF) process. Limited additional Cu cathode via 7mtpa of heap leaching (HL) and solvent extraction/electrowinning (SX/EW). There will also be Au credits in the Cu concentrate.

- 89% average recovery from Mill/Float (MF) and 74% recovery from Heap Leach (HL).

- 150MW of maximum power demand to be sourced through nearby Namibian grid, plus supplementary hybrid renewable power and battery energy storage.

- 20m m3 of process water per year from a hybrid solution of Orange river water (30km distance) and potentially piped from Namibia’s Neckartal storage dam (260km distance).

-

Permitting process underway with Namibian mining license application submitted and environmental & social impact assessment (ESIA) processes proceeding.

- Specialist environmental and social studies and public consultation process advancing with positive results. Public perception generally positive with interest in job creation, broader economic development opportunities and community and infrastructure development.

- All study and technical work directed by Koryx’s highly experienced in-house team working with world-class specialists, lead by DRA Global Limited (“DRA”) (overall co-ordinating consultant), Knight Piésold (“KP”), Qubeka Mining Consultants (“Qubeka”), the MSA Group (“MSA”), SRK Consulting (“SRK”) and MJO Ingeniería y Consultores en Metalurgia (“MJOI”).

-

Live webinar to discuss the PEA results. Participants must register for the event beforehand using the link below. Date & Time: Friday, September 5, 2025 at 10:00am EST

Register: https://us06web.zoom.us/webinar/register/WN_qUZaHmJdTTyMb21V_tNvlw

Please join the Koryx team for the discussion & presentation followed by Q&A.

VANCOUVER, British Columbia, Sept. 04, 2025 (GLOBE NEWSWIRE) -- Koryx Copper Inc. (“Koryx” or the "Company") (TSX-V: KRY) is pleased to announce the results of the recently completed Preliminary Economic Assessment (“PEA”) of the Company’s 100%-owned, flagship Haib Copper Project (“Haib” or the “Project”) in southern Namibia.

Heye Daun, Koryx Copper’s President and CEO commented as follows: "We are highly encouraged with the very good results of this PEA, notwithstanding the fact that it is still based on the 2024 Mineral Resource model and does NOT yet reflect all of the excellent drill results produced since late 2024. The objective of this PEA was (i) to right-size and optimize the Haib project and reposition it as a credible, low-risk, large-scale, low-cost, high-return, open pit milling & flotation operation, and (ii) to demonstrate Koryx’s material undervaluation when compared to other Cu development equities.”

“With a Cu production rate of 92,000 tonnes per annum, a post-tax NPV8% of +US$1.35n, upfront capital cost of US$1.56bn, low C1 cash cost of US$1.81/lb of Cu (AISC of US$2.05/lb of Cu during the first 10 years of production and a long mine life of 23 years, Haib stands out as an emerging, top-quality, near-term African copper development project.”

“What makes this project truly unique however are a few of its key attributes, namely its simplicity, scalability, low risk, ideal location at low altitude, close to water and power infrastructure, with low capital intensity, low operating costs, a predictable permitting environment and lack of any technical, environmental or social fatal flaws. This suggests that this project could be rendered shovel-ready, with an advanced feasibility study, secure water and power supply and most major permits in place within just a few years.

”Lead by a strong and motivated technical team that has the drive and in-country experience of having recently advanced and permitted a major gold mine development in Namibia (Osino Resources’ Twin Hills gold project which is presently in construction), we look forward to successfully delivering another excellent large-scale mine development project in Namibia (now our 3rd one in the past 15 years).”

Property Description and Ownership

Haib is a porphyry copper exploration project located in the Karas Region of southern Namibia approximately six kilometres north of the border with South Africa and between 12km and 15km east of the tarred B1 highway that connects Namibia with South Africa. Koryx Copper Inc. has a 100% interest in Deep South Mining Company (Pty) Ltd., a Namibian subsidiary which in turn has a 100% interest in Haib Minerals (Pty) Ltd (“Haib Minerals”) which holds the exploration rights to the Haib Project. Exclusive Prospecting Licence 3140 (“EPL 3140”) allows for the exploration of base, rare and precious metals over an area of 36,589 hectares.

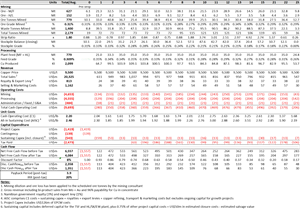

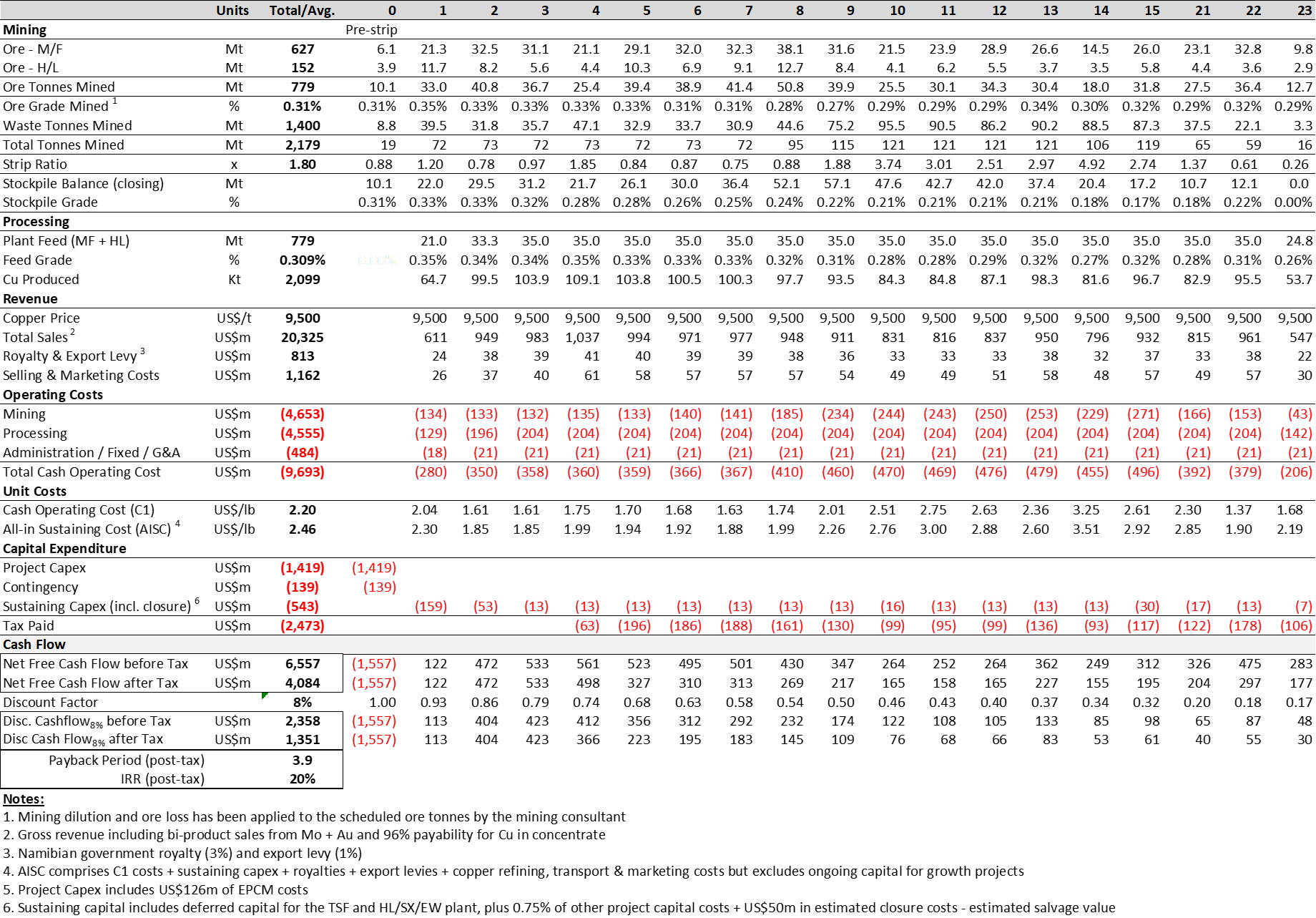

Results of PEA Financial Evaluation

A PEA financial model was developed from the updated studies with the following techno-economic results.

| Table 1: PEA Financial Valuation Results | |||||

| US$9,500/t | US$10,000/t | ||||

| Units | Pre-Tax | Post-Tax | Pre-Tax | Post-Tax | |

| NPV8% | US$m | 2,358 | 1,351 | 2,986 | 1,742 |

| IRR | % | 25.2% | 20.1% | 28.9% | 23.0% |

| Payback Period | years | 3.8 | 3.9 | 3.4 | 3.6 |

| LOM Cashflow | US$m | 6,557 | 4,084 | 7,948 | 4,944 |

| Upfront Capex 3 | US$m | 1,557 | |||

| Sustaining Capex 4 | US$m | 543 | |||

| Ave Annual Payable Cu Production | ktpa | 88 | LOM | ||

| C1 Cash Costs (Avg Years 1-10) 1 | US$/lb | 1.81 | Years 1 - 10 | ||

| AISC Costs (Avg Years 1-10) 2 | US$/lb | 2.05 | Years 1 - 10 | ||

| Capital Intensity | US$/t | 16,057 | Years 1 - 10 | ||

| Capital Intensity | US$/t | 16,740 | LOM | ||

| Table 2: Key Assumptions & Parameters | |||||||

| Mill/Float | Heap Leach | ||||||

| Item | Units | Total | M/F | H/L | |||

| Life of Mine | Years | 23 | |||||

| Copper price (base case) | US$/t | 9,500 | |||||

| Copper Recovery total | % | 84.2% | |||||

| Copper Recovery M/F | % | 88.8% | 88.8% | ||||

| Copper Recovery H/L | % | 77.7% | 77.7% | ||||

| Government Royalty (tax-deductable) | % | 3.0% | |||||

| Export Levy | % | 1.0% | |||||

| Table 3: LOM Production Parameters | |||||||

| Total | M/F | H/L | |||||

| Mineralised Material Tonnes Mined | Mt | 779 | |||||

| Mineralised Material Cu Grade Mined | % Cu | 0.309% | |||||

| Contained Copper Metal | kt | 2,405 | |||||

| Waste Tonnes Mined | Mt | 1,400 | |||||

| Strip Ratio | x | 1.80 | |||||

| Concentrate grade | % Cu | 21% | |||||

| LOM Copper in conc (Mill float) | kt | 1,842 | 1,842 | ||||

| LOM Copper cathode (Heap Leach) | kt | 257 | 257 | ||||

| LOM Payable Copper Production total | kt | 2,026 | |||||

| Avg payable Cu Production pa (first 10 years) | ktpa | 92 | Years 1 - 10 | ||||

| Avg payable Cu Production pa (LOM) | ktpa | 88 | LOM | ||||

| Table 4: Capital Cost Estimates | |||||||

| Capital Costs | Total | M/F | H/L | ||||

| Construction Capital (DRA Estimate) 3 | US$m | 968 | 808 | 159 | |||

| Capitalised Pre-strip | US$m | 33 | |||||

| Rail siding | US$m | 4 | |||||

| Mining capex | US$m | 29 | |||||

| Owners cost | US$m | 31 | |||||

| Surface infrastructure | US$m | 301 | |||||

| Site infrastructure | US$m | 52 | |||||

| Contingency | US$m | 139 | |||||

| Total Project Capital (incl. contingency) | US$m | 1,557 | |||||

| Sustaining Capital (LOM) 4 | US$m | 543 | 362 | 181 | |||

| Table 5: Unit Costs | |||||||

| Unit Costs per Tonne Mined/Processed | Total | M/F | H/L | ||||

| Mining Cost (per tonne mined) | US$/t | 2.15 | 2.15 | 2.15 | |||

| Variable Processing Cost (per t processed) | US$/t | 5.85 | 6.14 | 4.64 | |||

| Fixed Processing Cost (G&A) | US$m | 9.55 | 6.21 | 3.34 | |||

| Unit Costs per ton Payable Cu Produced | Total | M/F | H/L | ||||

| C1 Cash Costs (Avg Years 1-10) 1 | US$/t | 3,980 | 4,161 | 2,843 | |||

| C1 Cash Costs (Avg LOM) 1 | US$/t | 4,841 | 5,045 | 3,438 | |||

| All-in Sustaining Costs (Avg Years 1-10) 2 | US$/t | 4,519 | 4,708 | 3,332 | |||

| All-in Sustaining Costs (Avg LOM) 2 | US$/t | 5,415 | 5,629 | 3,944 | |||

| Unit Costs per lb Payable Cu Produced | Total | M/F | H/L | ||||

| C1 Cash Costs (Avg Years 1-10) 1 | US$/lb | 1.81 | 1.89 | 1.29 | |||

| C1 Cash Costs (Avg LOM) 1 | US$/lb | 2.20 | 2.29 | 1.56 | |||

| All-in Sustaining Cost (Avg Years 1-10) 2 | US$/lb | 2.05 | 2.14 | 1.51 | |||

| All-in Sustaining Costs (Avg LOM) 2 | US$/lb | 2.46 | 2.55 | 1.79 | |||

| Notes: | |||||||

| 1. C1 = Mining, processing plus on-site G&A and selling costs less by-product credits | |||||||

| 2. AISC = C1 costs plus royalties & levies and sustaining capex (excluding closure costs & reclamation value) | |||||||

| 3. Project Capital includes US$126m of EPCM costs | |||||||

| 4. Sustaining capital includes deferred capital for the TSF and HL/SX/EW plant, plus 0.75% of other project capital costs + US$50m in estimated closure costs - estimated salvage value | |||||||

Capital and Operating Cost Estimates

The capital cost estimate for the project was compiled by DRA, with inputs from Koryx and supporting specialist consultants KP and Qubeka.

The estimate for the main crushing, milling and flotation plant for higher grade (“HG”) mineralization was developed by DRA for a plant designed to process 28 Mtpa of ROM, with about 4 Mtpa of >150µm barren coarse particle flotation tailings being rejected ahead of conventional flotation of 24 Mtpa at a target grind of about 80% < 150µm.

The capital cost estimate for the 7 Mtpa low grade (“LG”) heap leach, copper solvent extraction and electrowinning and iron removal circuit was based on the estimates prepared by METS for the previous PEA of this project, updated by Koryx with input from DRA.

KP developed the capital cost estimates for the Tailings Storage Facility (“TSF”), access roads, water and bulk power supply, stormwater management, housing and site accommodation. DRA and Qubeka prepared estimates for infrastructure directly associated respectively with the process plants and contract mining area.

Each consultant submitted estimates of engineering, project and construction management (“EPCM”) services costs associated with their scope of work. This was supplemented by a detailed estimate by Koryx of Owner’s costs during project implementation.

The cost estimate for pre-strip of waste rock before commencing production mining operations was an outcome of Qubeka’s detailed mining schedules.

Significant portions of the heap leach/SX/EW, TSF and other infrastructure costs will only be incurred in the first or second year of operation, hence these were recorded as sustaining capital in the table below. Other sustaining capital costs in subsequent years of operation were estimated by DRA and KP.

Table 6: Project Capital Cost Breakdown (US$m)

| Item Description |

Upfront Construction Capex |

Heap Leach Capex (Y1 + Y2) | Sustaining Capex | Total Capex | |

| Mill float capital cost estimate | 737 | 0 | 89 | 826 | |

| HL/SX/EW capital cost estimate Y1 | 145 | 137 | 31 | 313 | |

| Tailings Facility | 30 | 0 | 200 | 230 | |

| Mining capex | 29 | 0 | 11 | 41 | |

| Owners cost | 31 | 0 | 0 | 31 | |

| Surface Infrastructure | 246 | 0 | 32 | 278 | |

| Site infrastructure | 50 | 0 | 0 | 50 | |

| EPCM Costs | 116 | 14 | 30 | 159 | |

| Total Capital Cost (excl. Contingency) | 1,385 | 151 | 393 | 1,929 | |

| Estimated 10% Contingency | 139 | 0 | 0 | 139 | |

| Capitalized Pre strip Mining | 35 | 0 | 0 | 35 | |

| Capex Total | 1,559 | 151 | 393 | 2,102 | |

Process plant operating cost estimates for the 28 Mtpa HG and 7 Mtpa LG plants were developed by DRA and Koryx, with associated labour rates and complements being prepared by Koryx. KP provided minor operating cost estimates for the related infrastructure. The process plants are expected to operate for 24 hours per day, 365 days per year.

Table 7: Project Operating Costs (US$/t processed)

| Cost Centre |

28 Mtpa High Grade Milling and Flotation Plant |

7 Mtpa Low Grade Heap Leach / SX EW Plant |

||||

| US$/t processed |

US$m /year |

US$/t processed |

US$m /year |

|||

| Material Handling Including Grade Control | 0.45 | 12.6 | 0.95 | 6.65 | ||

| Operating and Maintenance Labor | 0.44 | 12.32 | 0.53 | 3.71 | ||

| Power | 2.33 | 65.24 | 1.49 | 10.43 | ||

| Consumables and Reagents Including Water | 1.96 | 54.88 | 1.29 | 9.03 | ||

| Maintenance | 0.66 | 18.48 | 0.33 | 2.31 | ||

| Laboratory Analyses | 0.11 | 3.08 | 0.05 | 0.35 | ||

| Tailings Storage Facility | 0.19 | 5.32 | ||||

| MF Plant G&A Expenses | 0.22 | 6.16 | 0.48 | 3.34 | ||

| Total Variable and Fixed Processing Costs | 6.36 | 178.08 | 5.12 | 35.82 | ||

Mining operating costs were estimated by Qubeka based on the envisaged mining contractor’s selected equipment fleet and organisational structure. The estimate was done from first principles, using the original equipment manufacturers (“OEM”) hourly life cycle cost estimates with the simulated production rates for the primary mining equipment.

Site administration (G&A) costs were estimated by Koryx, based on other similar sized copper operations. The unit operating cost estimates thus derived are summarized in the table below:

Table 8: Total Operating Cost Estimate

| Cost Centre (average costs over life of mine) | Unit |

Unit Cost |

US$m /year |

||

| Waste Rock Mining | US$/t mined | 2.25 | 140.00 | ||

| Mineralized Mining | US$/t mined | 2.25 | 79.93 | ||

| MF Processing Plant | US$/t processed | 6.36 | 178.08 | ||

| HL Processing Plant | US$/t processed | 5.12 | 35.82 | ||

| Infrastructure Variable Costs | US$m/year | 8.52 | |||

| Non Process G&A Costs | US$m/year | 3.13 | |||

| Total Variable and Fixed Operating Costs | 445.48 | ||||

| Total Unit Operating Cost | US$/lb Cu | 2.26 | |||

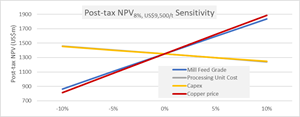

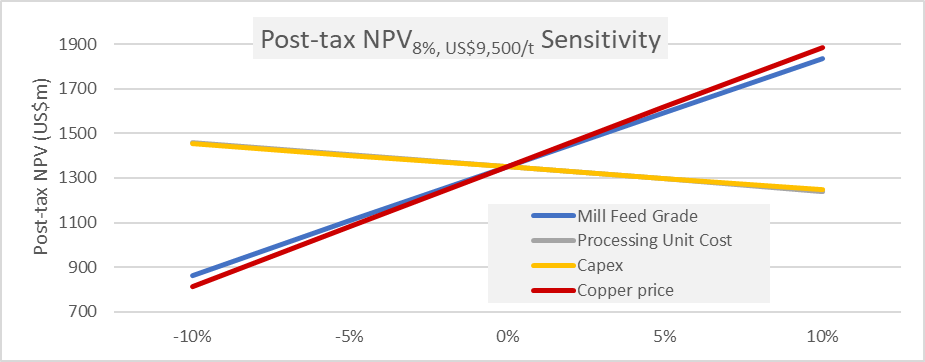

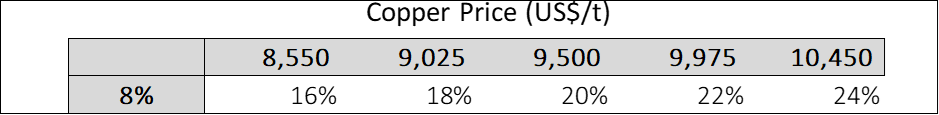

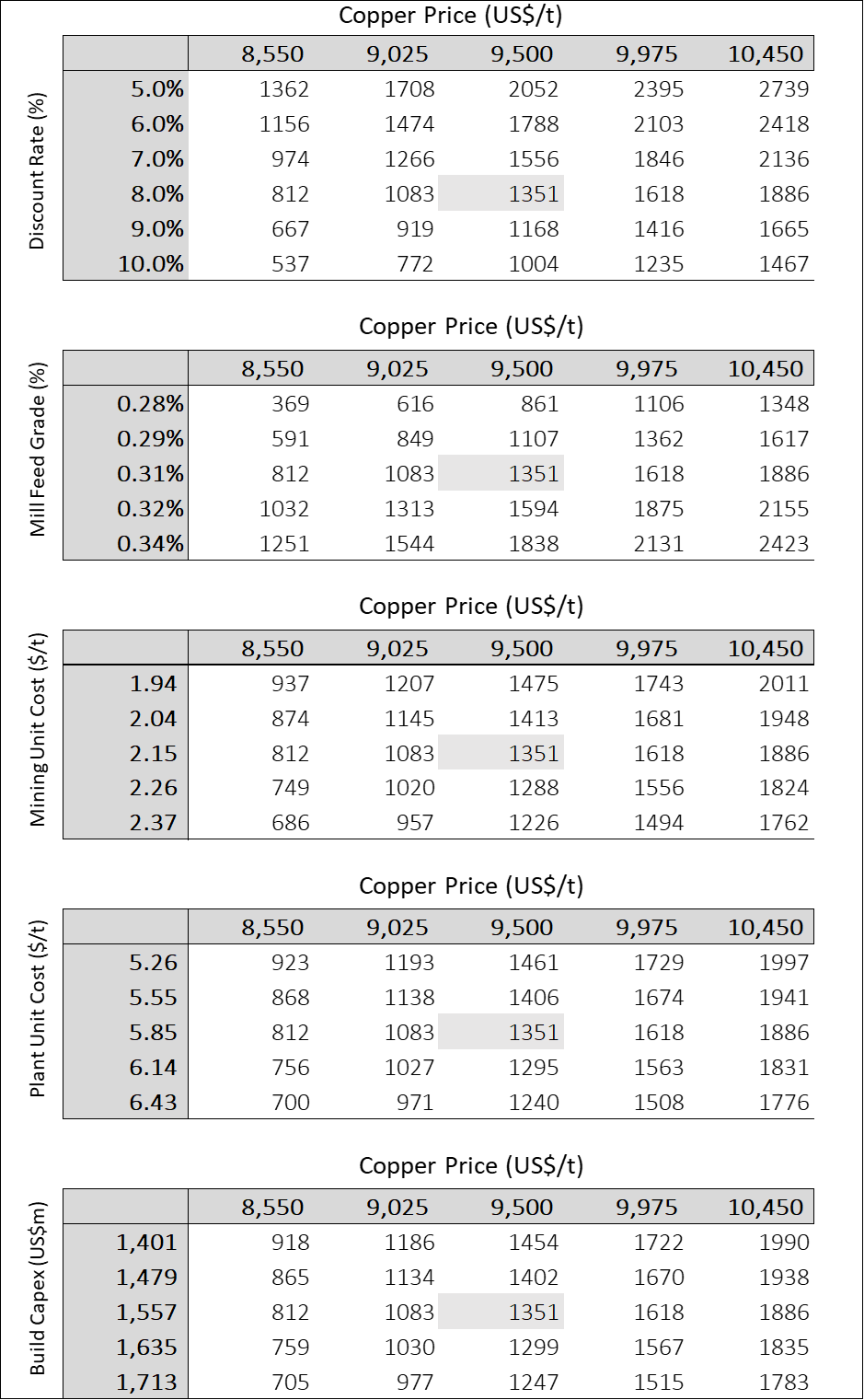

Financial Sensitivity Analysis

Figure 1: Financial Sensitivity Spider Diagram

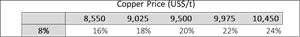

Table 9: IRR Sensitivity to Copper Price (Post-Tax)

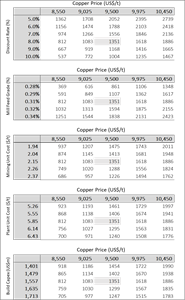

Table 10: NPV8% Sensitivity Table (Post-Tax)

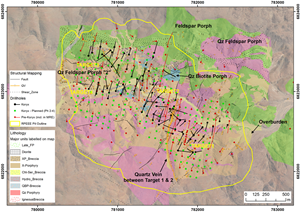

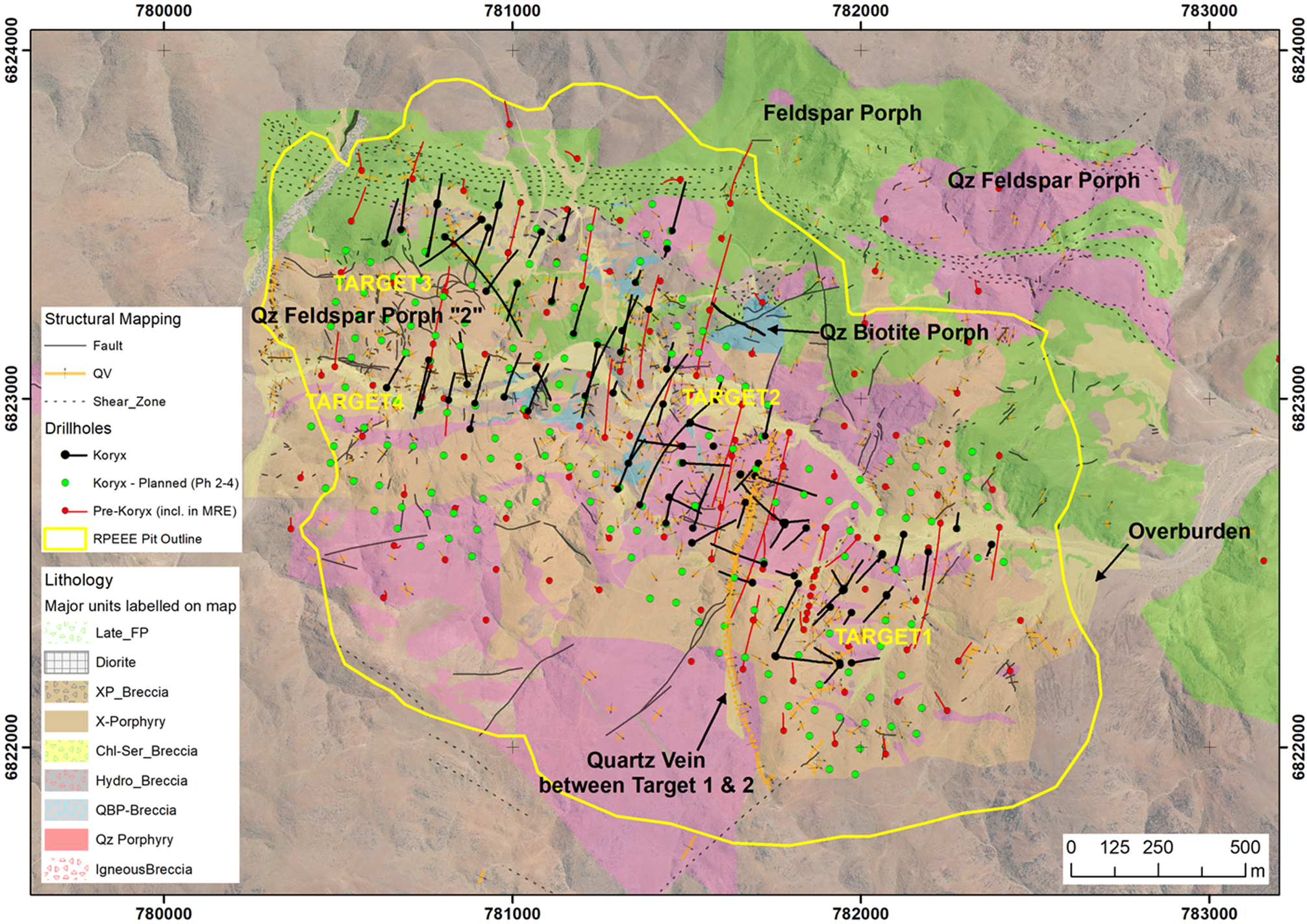

Geology and Mineralization

Haib is hosted within the coeval, Paleoproterozoic Orange River Group volcanic and Vioolsdrif Intrusive Suite of plutonic rocks of the Richtersveld Sub province of the Namaqua-Natal Province. The Orange River Group consists of several northwest trending felsic to mafic volcanic belts. The Vioolsdrif Intrusive Suite intrudes the Orange River Group and is composed of felsic to mafic batholiths dominantly composed of granodiorite.

At Haib the Vioolsdrif Intrusive Suite is made up of several phases of porphyritic intrusive rocks, including the main mineralized host rocks, termed the Quartz Feldspar Porphyry (QFP) and the Feldspar Porphyry (FP).

Figure 2: Haib Cu Project Geology & Drill Plan

The entire region has undergone two phases of greenschist facies metamorphism, which have mainly produced a metamorphic assemblage of chlorite-calcite-epidote-green biotite without significant deformation. Most of the rock exhibits typical porphyry copper type alteration zones associated with mineralization.

The higher-grade copper mineralization is controlled by a fracture / vein set that parallels a regional structural trend and strikes approximately northwest and dips steeply (-70°) to the southwest. This high-grade zone also appears to plunge at 30° to 40° towards the south-east.

Broad zones of copper mineralization occur over a strike length of approximately two kilometers that are commonly several hundreds of meters wide. Mineralization has been intersected by diamond drilling to a maximum depth of 790 m below the topographic surface. Copper mineralization is predominantly as chalcopyrite in both disseminated and vein form, however pyrite, minor bornite, chalcocite and molybdenite also occur.

Mineral Resource Estimate

The Haib Mineral Resource estimate included information obtained from diamond drillholes completed between 1963 and 2024 with drilling comprising a total length of 78,934 m. In addition, one underground adit was channel sampled over a length of 126 m. The historical data was extensively validated, and all data collected by Rio Tinto Zinc (120 drillholes from 1972 to 1975), Great Fitzroy Mines (13 drillholes from 1995 to 1999) and Teck (32 drillholes in 2010) were accepted for use in the Mineral Resource estimate.

A summary of the Mineral Resource estimate is presented in the Table below.

Table 11: Mineral Resource Estimate for Haib (as at 01 September 2025 at a 0.15% Cu cut-off)

| Category | Type |

Tonnes (Mt) |

Cu Grade (%) |

Mo Grade (ppm) |

Cu Content (Mlbs) |

Mo Content (Mlbs) |

Cu Content (kt) |

Mo Content (kt) |

|

Measured |

Oxide & Transitional (>0.15% Cu) | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Low Grade (0.15 to 0.225% Cu) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| High grade (>0.225 % Cu) | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

| Total | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |

|

Indicated |

Oxide & Transitional (>0.15% Cu) | 23.5 | 0.31 | 16 | 159 | 0.8 | 72 | 0.4 |

| Low Grade (0.15 to 0.225 % Cu) | 45.3 | 0.21 | 46 | 211 | 4.6 | 96 | 2.1 | |

| High grade (>0.225 % Cu) | 442.3 | 0.34 | 53 | 3307 | 51.7 | 1500 | 23.5 | |

| Total | 511.0 | 0.33 | 51 | 3678 | 57.1 | 1668 | 25.9 | |

|

Measured & Indicated |

Oxide & Transitional (>0.15% Cu) | 23.5 | 0.31 | 16 | 159 | 0.8 | 72 | 0.4 |

| Low Grade (0.15 to 0.225 % Cu) | 45.3 | 0.21 | 46 | 211 | 4.6 | 96 | 2.1 | |

| High grade (>0.225 % Cu) | 442.3 | 0.34 | 53 | 3307 | 51.7 | 1500 | 23.5 | |

| Total | 511.0 | 0.33 | 51 | 3678 | 57.1 | 1668 | 25.9 | |

|

Inferred |

Oxide & Transitional (>0.15% Cu) | 16.3 | 0.28 | 16 | 102 | 0.6 | 46 | 0.3 |

| Low Grade (0.15 to 0.225 % Cu) | 37.7 | 0.21 | 45 | 175 | 3.8 | 79 | 1.7 | |

| High grade (>0.225 % Cu) | 254.8 | 0.32 | 41 | 1816 | 23.0 | 824 | 10.5 | |

| Total | 308.9 | 0.31 | 40 | 2093 | 27.4 | 949 | 12.4 |

Notes:

- All tabulated data have been rounded and as a result minor computational errors may occur.

- Mineral Resources, which are not Mineral Reserves, have no demonstrated economic viability. There is no guarantee that that all or any part of the Mineral Resource will be converted into a Mineral Reserve. The estimate of Mineral Resources may be materially affected by geology, environment, permitting, legal title, taxation, socio-political, marketing, or other relevant issues.

- Mt = Million tonnes, kt = thousand tonnes, Mlbs = Million pounds

-

The Mineral Resource Statement for Haib as of 01 September 2025 is reported at a cut-off grade of 0.15% Cu within a conceptual pit shell using the following assumed parameters:

- Base Copper Price USD/lb Cu: 4.20, Base Molybdenum price: USD/lb Cu: 20

- Royalty and Export Levy: 4%, Copper metal credit (payability): 97.5%, Molybdenum metal credit = USD/lb Cu: 0.17

- Mining dilution: 5%, Mining recovery: 95%, overall slope angle: 55°

- Sulphide recovery flotation: 89%, Heap Leach recovery 74%

- Mining Cost at pit rim USD/tonne: 2.07 (additional 0.008 USD/tonne per metre depth from pit rim)

- Stockpile and site-transport costs USD/tonne: 0.30

- Processing Cost USD/tonne mineralized material processed: 5.85 Flotation, 4.49 Heap Leach, solvent extraction and electro winning (SX-EW).

- SG&A Overheads USD/tonne mineralized material processed: 0.88 Flotation, 1.07 Heap Leach SX-EW

- Selling Cost Transport, smelting and refining of Concentrate USD/lb Cu: 0.30

- Low Grade zone refers to the portion of the block model within the modelled 0.2% Cu grade shells that is targeted to follow a leaching SX-EW process similarly to the oxide and transitional mineralization.

Samples from two drilling campaigns (King Resources and Falconbridge) comprising a total of 29 drillholes completed during the period 1963 to1969 were excluded from grade estimation as MSA was unable to satisfactorily validate these data. Koryx drilled 45 NQ size holes from 2021 to 2024, which verified the nature of the mineralisation in the historical database and infilled the drilling grid along the main mineralisation trend.

The pre-Teck and Koryx holes were largely drilled vertically and at a grid spacing of approximately 150 m. Teck and Koryx drilled angled holes, in some cases from the same location, to more optimally intersect the dipping mineralisation. Given the more targeted infill nature of the drilling and the challenging topography, the resultant grid is irregular.

Three-dimensional copper and molybdenum mineralisation models were created, and grades were estimated using the accepted historical and all Koryx data. Grade estimation of a three-dimensional block model was performed by ordinary kriging of two metre composite sample grades using Leapfrog Edge software. An average in-situ dry bulk density value of 2.78 t/m3 was assigned to all blocks.

This updated Mineral Resource Statement, with an effective date of 01 September 2025, represents re-reporting of the 2024 Mineral Resource model based on a revised optimised pit shell using parameters aligned with the 2025 Preliminary Economic Assessment. Molybdenum has been included in this update following metallurgical test-work allowing for assumed recovery to be applied.

The Mineral Resource was estimated using the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Best Practice Guidelines and is reported in accordance with the 2014 CIM Definition Standards, which have been incorporated by reference into National Instrument 43-101 – Standards of Disclosure for Mineral Projects (NI 43-101).

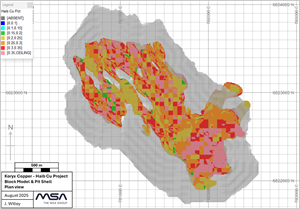

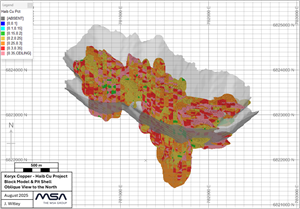

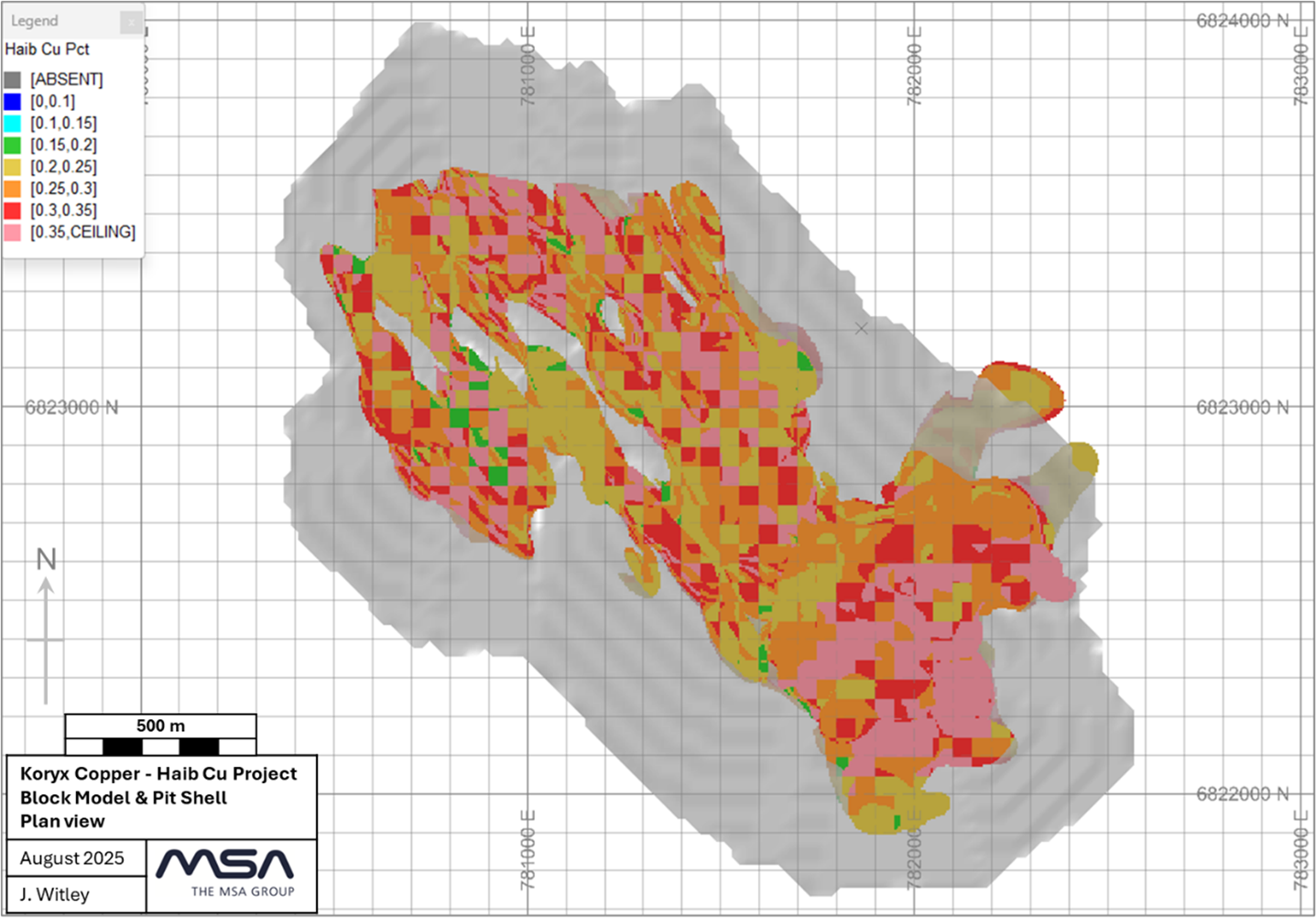

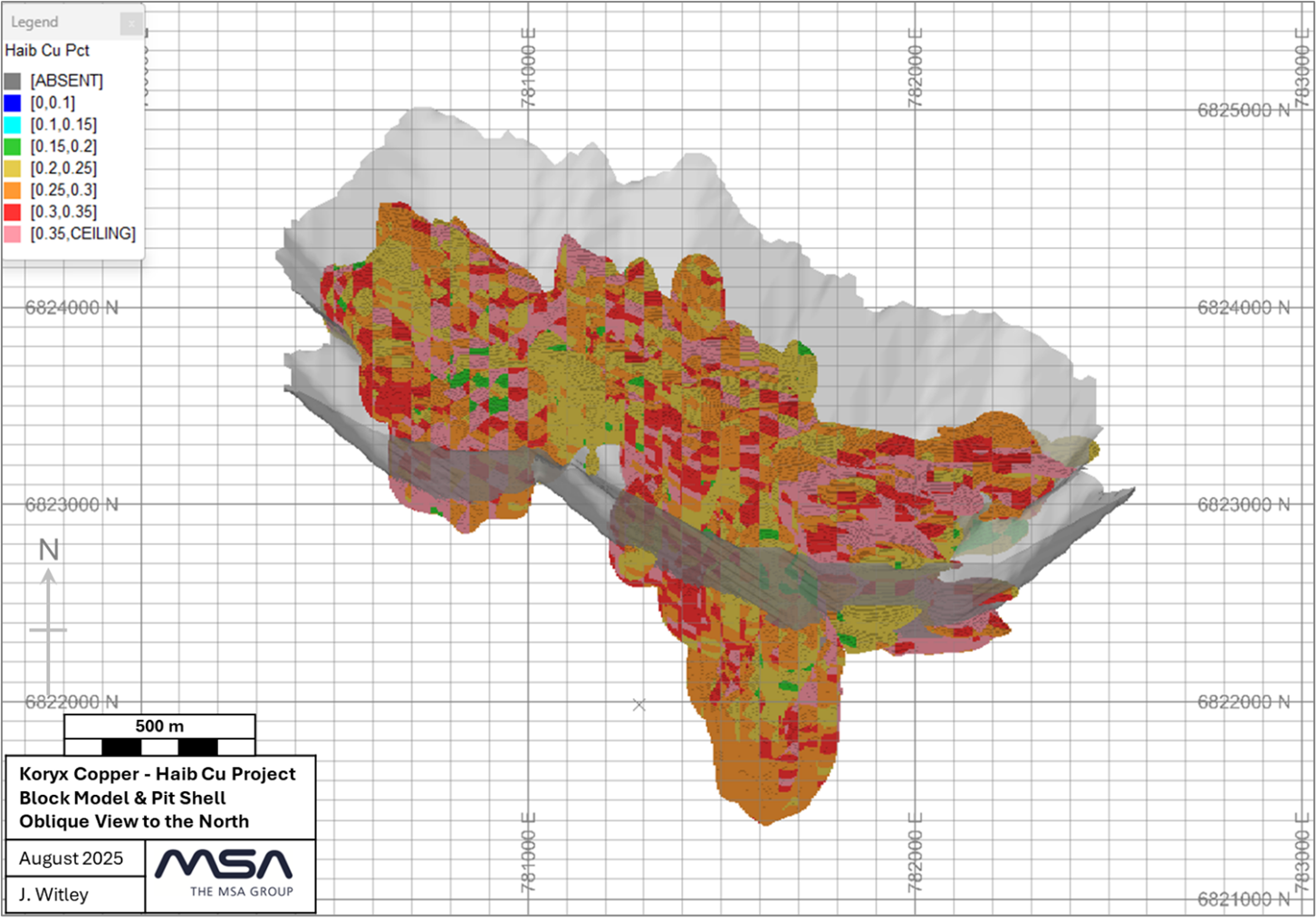

Pit Optimization and Mine Planning

The PEA envisages an open-pit mining operation with flotation of sulphide mineralization with a grade of greater than 0.225% copper, and heap leach with solvent extraction electro winning (SX-EW) of oxide and transitional mineralization with a grade greater than 0.15% Cu and low grade (0.15% Cu to 0.225% Cu) sulphide mineralization.

The optimised pit shell only considered mineralization contained within the modelled 0.20% Cu grade shell. While it is recognised that significant quantities of generally lower grade material exist outside the grade shell, this is for the time being not being included in the PEA mine schedule and has not been included in this Mineral Resource statement.

From the assumed parameters, a 0.1% Cu in-situ cut-off grade was calculated, which, together with the optimised pit shell demonstrates reasonable prospects for eventual economic extraction (RPEEE) for the Mineral Resource. The assessment to satisfy the criteria of RPEEE is a high-level estimate and is not an attempt to estimate Mineral Reserves. The Haib RPEEE pit shell is illustrated together with the block model in the Figures below.

An optimisation and mining study was completed by Qubeka and notes that the PEA is preliminary in nature and is based on Indicated and Inferred Mineral Resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorised as Mineral Reserves. Inferred Mineral Resources were included in the pit optimisation runs and also classified as mineralized material during the LOM production schedule runs.

The deposit is a large copper-molybdenum porphyry deposit in southern Namibia amenable to open-pit mining. The mineralization will be mined as a conventional shovel and truck operation, with bulk mining augmented by more selective mining in areas with narrow mineralized material zones.

Figure 3: Haib resource pit shell and block model – plan view

Figure 4: Haib resource pit shell and block model –oblique view to the north

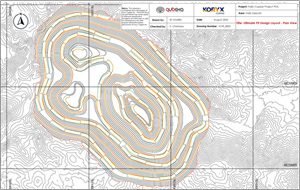

It was assumed that mining would take place by conventional open-pit methods and that the whole mining operation, except for the mine technical services function, would be outsourced to a reputable mining contractor company.

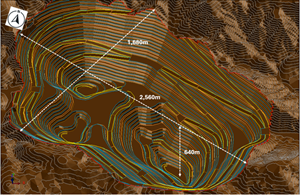

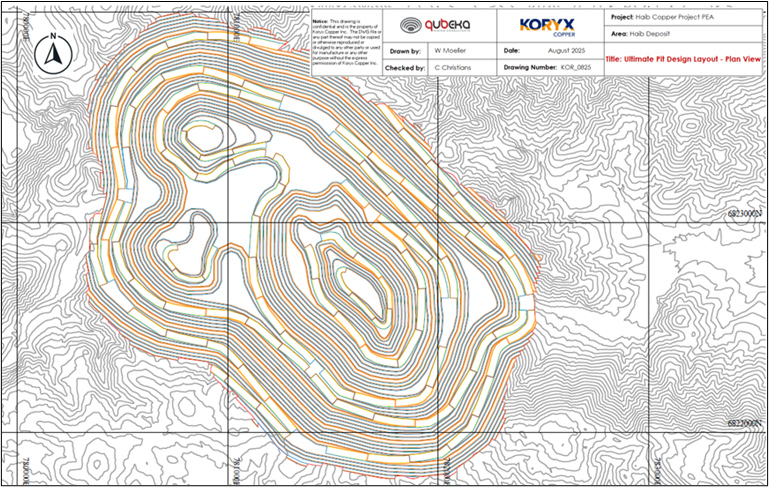

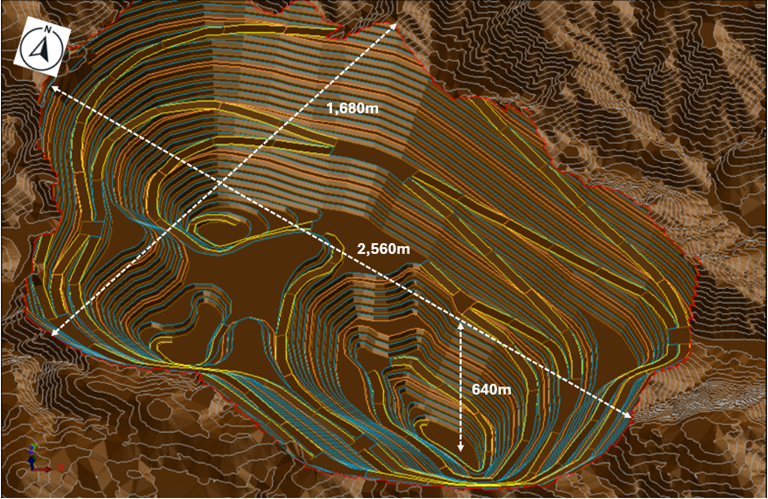

Figure 5: Ultimate Pit Design Layout (Plan View)

Figure 6: Ultimate Pt Design & Dimensions

Mine feed and waste will be loaded with hydraulic face shovels and hauled by diesel-powered trucks to the primary crusher, ROM pad stockpiles, low-grade stockpiles or waste rock dumps. The remainder of the mining production fleet consists of support equipment, including graders, track and wheel dozers, front-end loaders, rock breakers, and utility excavators.

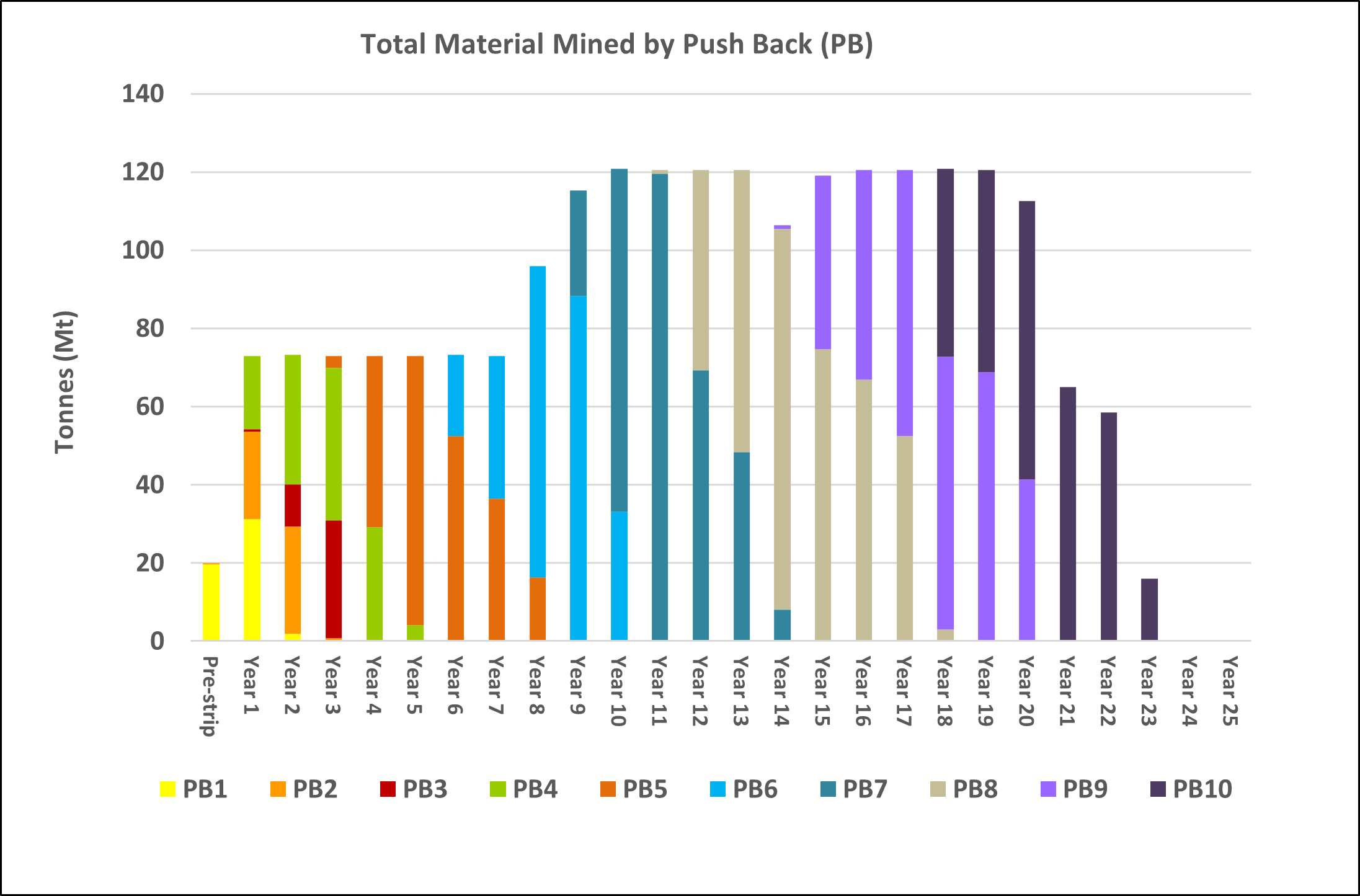

The pit design and scheduling have been undertaken to allow for interim pushbacks, which will be mined early, thereby allowing higher grade to the plant to be maximised in the early years, and waste stripping deferred as far as possible into the future.

The Table below summarises the pit inventory at a cut-off grade of 0.150% Cu, with modified Indicated and Inferred material being classified as mineralized material.

Table 14 : Pit inventory at a cut-off grade of 0.150 %Cu (Indicated and Inferred Material)

| Production Parameter | Units | Total | |

| Milling Flotation (> 0.225 %Cu) Fresh Material | Mt | 626.81 | |

| Indicated Material | Mt | 406.63 | |

| Inferred Material | Mt | 220.18 | |

| Milling Flotation (> 0.225 %Cu) Fresh Material | Mt | 626.81 | |

| Heap Leach (0.150 - 0.225 %Cu) Fresh Material | Mt | 93.97 | |

| Indicated Material | Mt | 51.78 | |

| Inferred Material | Mt | 42.19 | |

| Heap Leach (0.150 - 0.225 %Cu) Fresh Material | Mt | 93.97 | |

| Oxide Material | Mt | 19.12 | |

| Transitional Material | Mt | 18.92 | |

| Heap Leach (> 0.150 %Cu) Oxide & Transitional Material | Mt | 38.07 | |

| Indicated Material | Mt | 22.64 | |

| Inferred Material | Mt | 15.44 | |

| Heap Leach (> 0.150 %Cu) Oxide & Transitional Material | Mt | 38.07 | |

| Waste | Mt | 1 425.26 | |

| Total Material Mined | Mt | 2 184.11 | |

| Strip Ratio [(Mineralized Waste + Waste) : Mineralization (ML & HL)] | Ratio | 1.88 | |

| Grade - Cu - Milling Flotation > 0.225 %Cu) Fresh Material | %Cu | 0.33% | |

| Grade - Cu - Heap Leach (0.150 - 0.225 %Cu) Fresh Material | %Cu | 0.20% | |

| Grade - Cu - Heap Leach (> 0.150 %Cu) Oxide & Transitional Material | %Cu | 0.29% | |

| Grade - Cu | %Cu | 0.31% | |

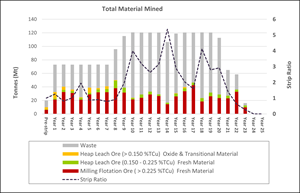

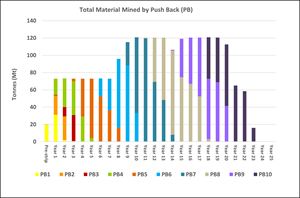

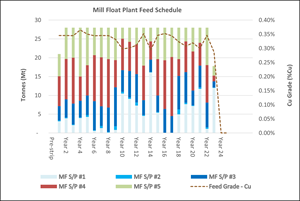

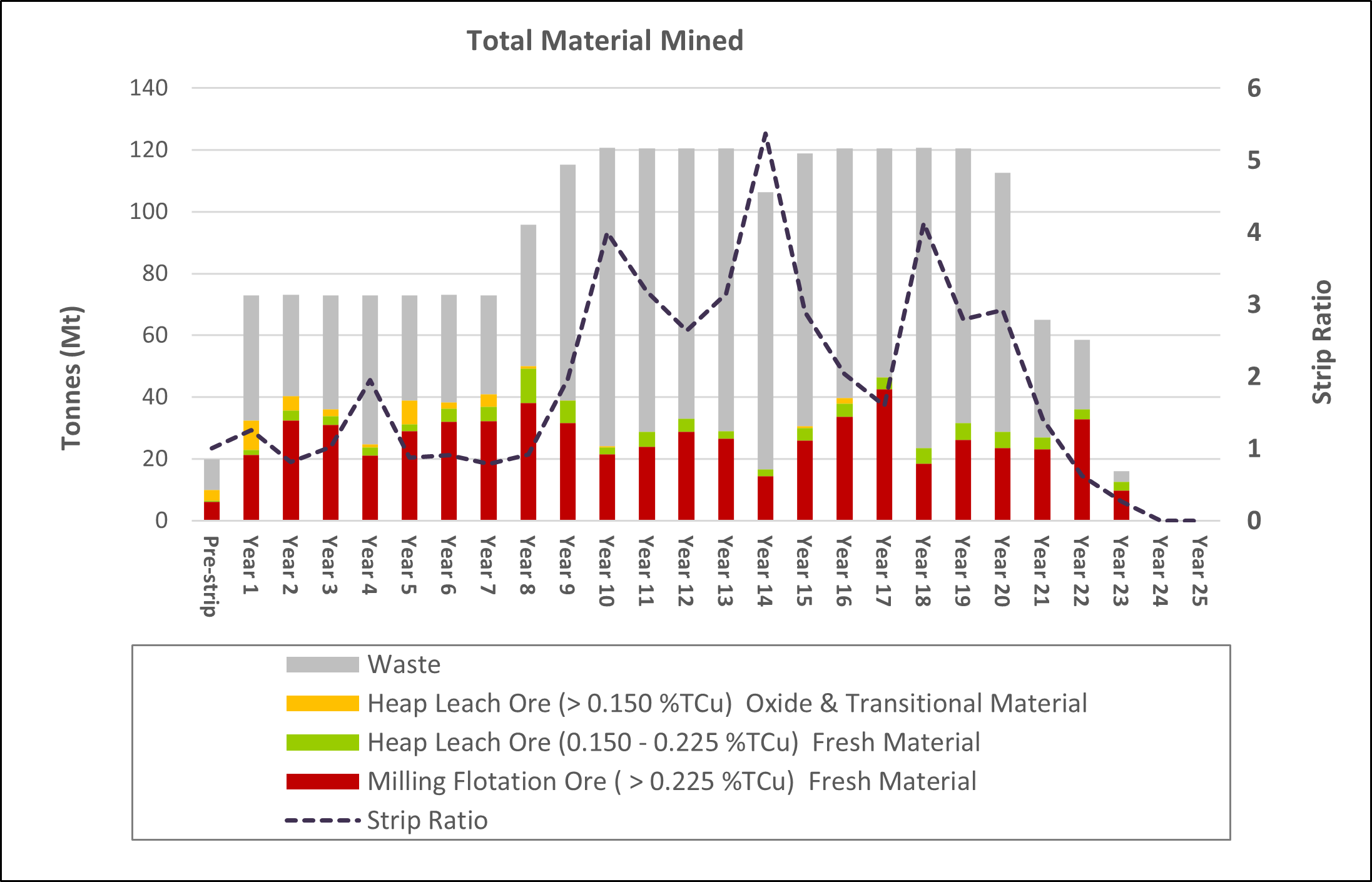

The final Haib copper mine production schedule was produced with a maximum material movement of approximately 120 Mtpa, providing approximately 23 years supply of mineralized material to the two envisaged processing routes.

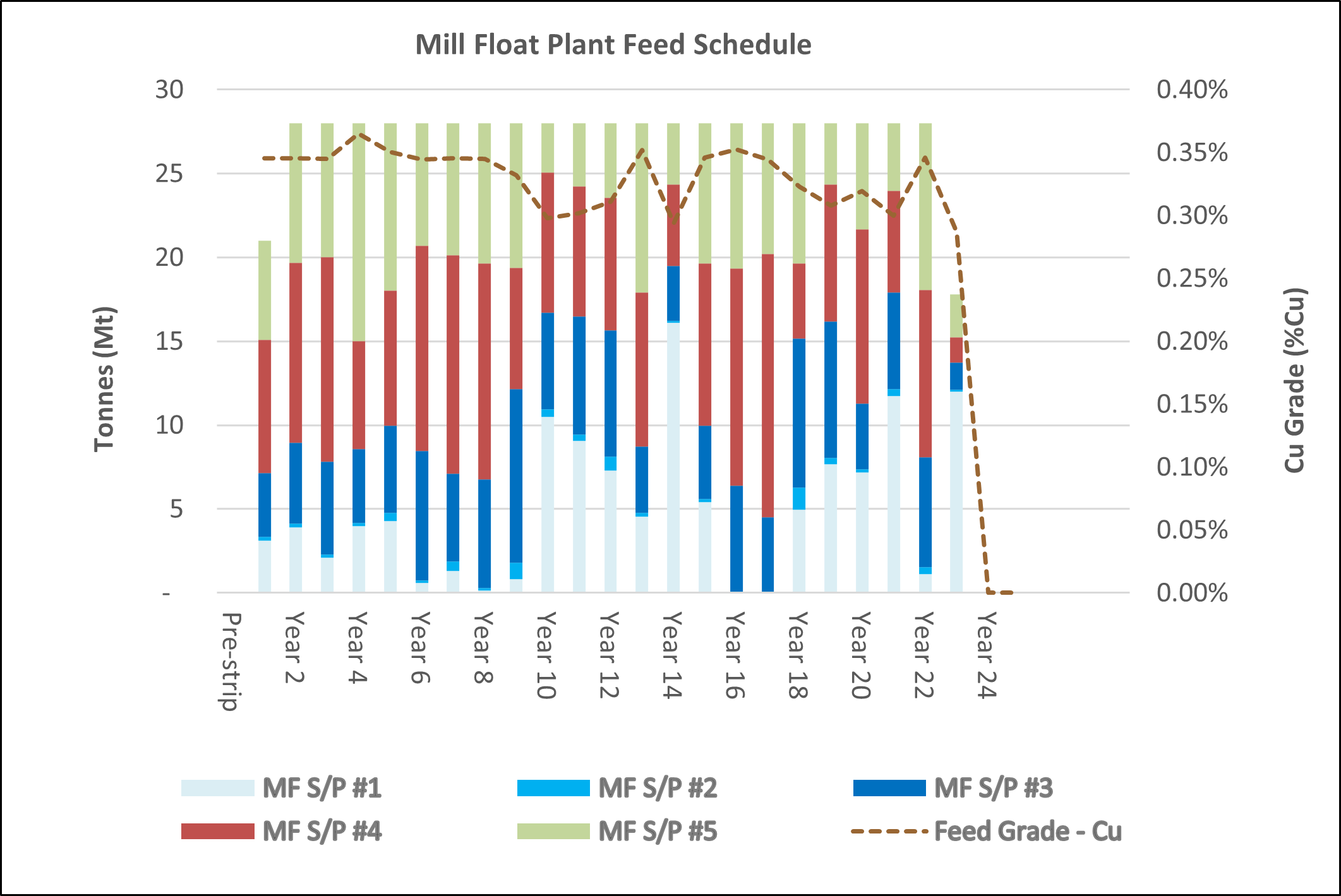

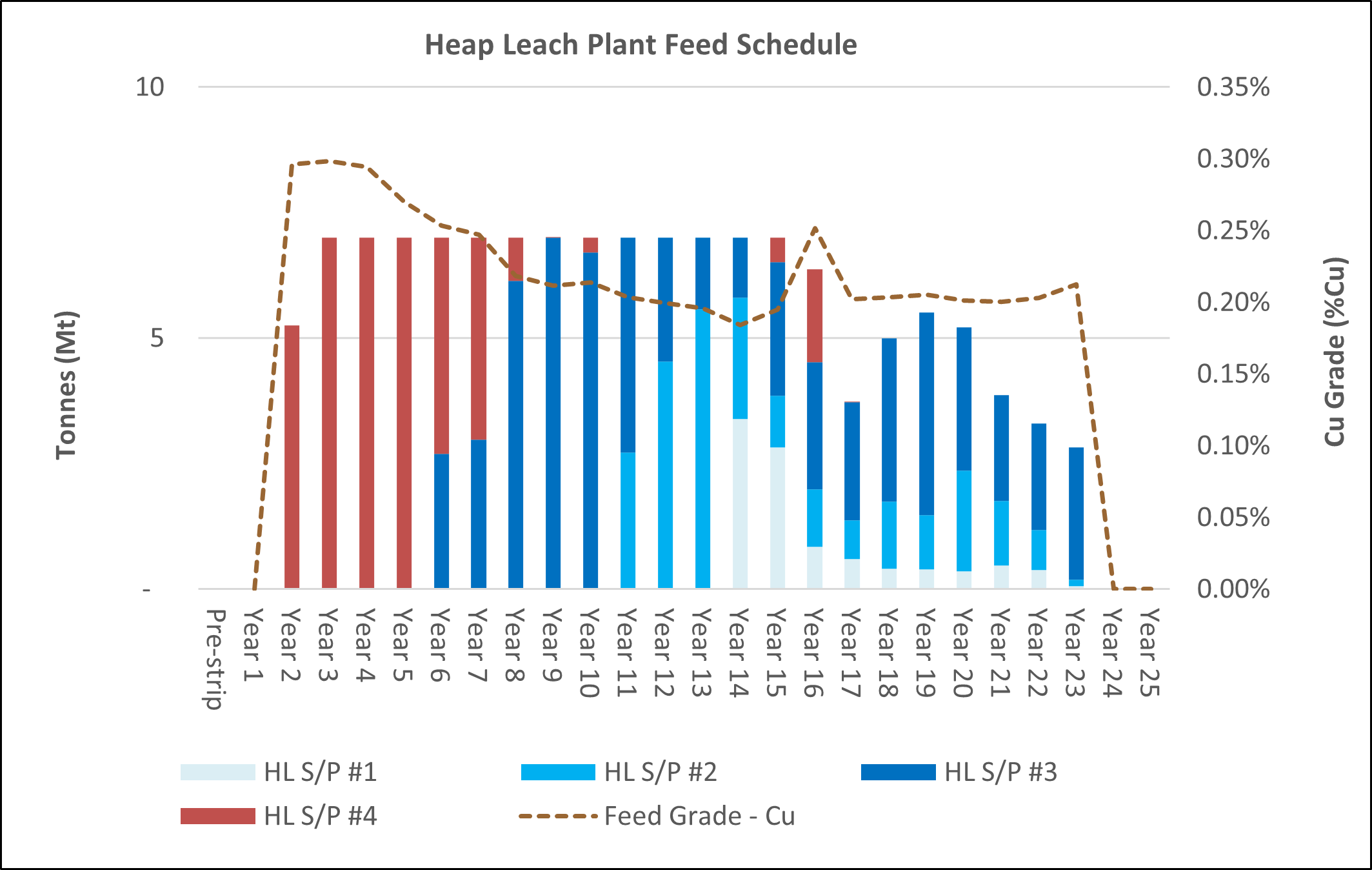

The diagrams below summarize the mining material flows, production schedules and key mine mining and processing metrics for the proposed Haib open pit copper mine.

Figure 7: Material Mined per Annum by Material Type & Strip Ratio

Figure 8: Material Mined Annum per Pushback (PB)

Figure 9: Mill & Float Plant Feed Schedule

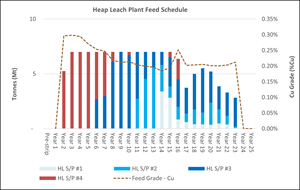

Figure 10: Heap Leach Plant Feed Schedule

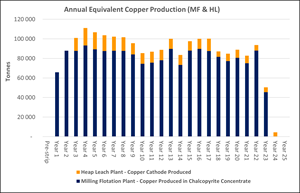

Figure 11: Annual Equivalent Copper Production

The pre-strip period is six months, with a total of 19.9 Mt mined from the first two pushbacks. After the pre-strip period, the mineralized inventory on the grade control and ROM stockpiles is 6.14 Mt of material destined for the milling and flotation plant. The plant production ramp-up is twelve months after commissioning.

Mineral Processing

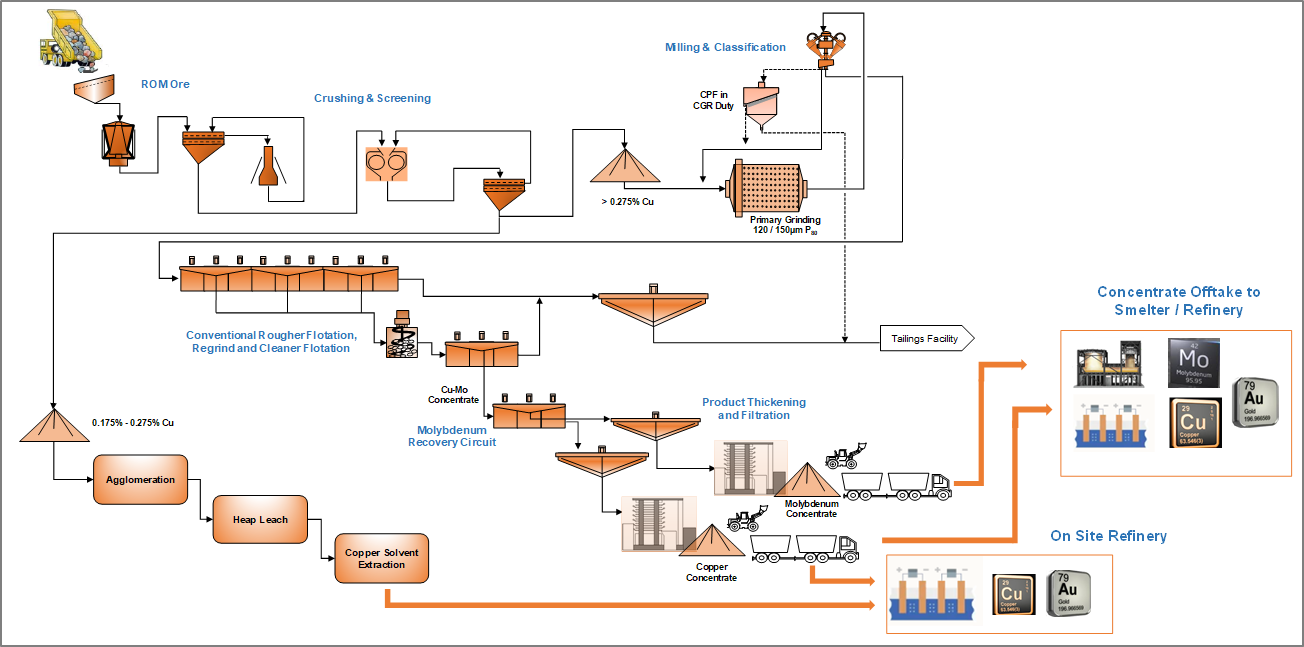

The following two processing routes are envisaged for the Haib project:

- Higher-grade sulfide material containing at least 0.225 %Cu will be treated by the concentrator plant (milling and flotation plant) sized to process 28.0 million tonnes per annum (Mtpa) of run-of-mine (ROM) material. The flowsheet consists of crushing, wet grinding, and flotation.

- All lower-grade sulfide material (0.150 – 0.225 %Cu) and transitional and oxide material (> 0.150 %Cu) will be treated by the hydrometallurgical plant (heap leach), with a throughput of 7.0 Mtpa consisting of three stages of crushing and screening followed by transport of crushed material, agglomeration and stacking on a heap leach pad.

- It is expected that the crushing, agglomeration and heap leach circuits will be commissioned in Year 1 of the Haib operation, with the solvent extraction and electrowinning being commissioned in Year 2.

Metallurgical Test work

Mineralogical evaluation of the Haib deposit extends back to 1975. The most recent scanning electron microscopy (SEM) analyses of samples compiled by Koryx from drill cores in 2024 and 2025 determined the following mineralogical features of the deposit:

- Chalcopyrite was found to be the predominant Cu bearing phase, accounting for 85 % to 99 % of the Cu present, with lesser amounts of Bornite, chalcocite and copper silicate minerals also present, particularly in the minor transitional portion mineralization where some oxidation was evident. Molybdenum was found to be present only in the form of molybdenite.

- The primary sulfide gangue mineral present was pyrite, typically associated with chalcopyrite, quartz or chlorite.

- The silicate gangue assemblage predominantly reflected quartz (30 to 40%), with lesser plagioclase, muscovite, orthoclase and chlorite.

- Physically, three types of copper mineral associations were identified. Chalcopyrite and pyrite were observed in veinlets, aggregates and disseminated form, associated with several different host rock mineral types. Generally, little or no variance was observed in respect of flotation or heap leach recovery from samples containing these different physical mineralization characteristics, but there was some variance in hardness and response to crushing and milling.

The samples tested in 2025 exhibited the following range of chemical analyses:

- Copper grade ranging from 0.17% to 0.67% associated with approximately 60 to 275 ppm molybdenum, 1.8 to 4.6% Fe and 0.4 to 1.4% S.

- Au grades were typical low measuring less than 0.05 g/t for almost all samples.

- Deleterious elements in plant feed reflected relatively low levels of As (< 50 ppm), Bi (< 10 ppm), Sb (< 3ppm), Cl (< 100 ppm) while F levels ranged from 800 to 1,300 ppm.

Comprehensive metallurgical tests have been undertaken since the mid 1990s. The following unit processes for treatment of sulfide minerals were investigated before Koryx became involved in the project:

- Comminution (crushing, milling and classification)

- Flotation of copper sulfide minerals

- Bacterial column and tank leach tests

- Rock sorting tests.

In 1996, minerals processing tests culminated in collection of a bulk mineralized sample from an adit within the planned open pit perimeter and a small-scale pilot plant test of the milling and copper flotation steps.

In 2024 and 2025, Koryx commissioned the following additional tests:

- Collection of multiple drill core samples exhibiting a range of copper grades, diverse sulfide mineralogy and a variety of host rock characteristics

- Confirmation of comminution parameters, mineral liberation and reagent suite settings for optimal copper flotation across the whole range of sulfide samples. This includes testing of high-pressure grinding rolls (HPGR) in a tertiary crusher application.

- Regrind, cleaner and recleaner flotation tests to produce potentially marketable copper sulfide concentrate

- Bulk and particle sorting of crushed mineralized material to reject barren waste and increase the copper grade of milling and flotation feed

- Heavy liquid separation tests to measure the potential of dense medium separation to be used as an alternative to rock sorting to upgrade milling and flotation feed

- Testing of Coarse Particle Flotation (“CPF”) in the milling circuit to reject coarsely milled barren waste ahead of conventional flotation

- Jameson cell tests as a potential alternative to conventional rougher flotation

- Establishment of gangue acid consumption, stacking and agglomeration/curing characteristics of low-grade sulfides

- Column leach tests to evaluate the efficacy of sulfuric acid/ferric sulfate, bacterial leach, three different chloride leach technologies and a nitrate assisted process on Haib transitional and sulfide mineralization.

Koryx has continued to work with GeoLabs, Maelgwyn, SGS, Eriez, Metso, RADOS, TOMRA, NextOre, Mintek and Ceibo to carry out the tests, and DRA and MJOI have continued to assist Koryx to interpret the test results.

Generally, the comminution and flotation results produced during the current test program have been excellent and matched or exceeded the results of the historical programs completed by Mintek in 1996.

Initial column leach results look promising, but it is too early to confirm if previous expectations have been achieved or exceeded. Specifically, the following results have been generated:

- Initial 2024/2025 Bond ball work index tests with screening at 106 µm (micrometre) generated Bond Ball Mill Work Index (BBWi) values between 17.5 and 19.4 kWh/t. Further BBWi tests on variability test samples replicated these results but exhibited more variance with a range between 17.8 and 23.3 kWh/t with 150 µm closing screen size. This supported indications that mineralization and host rock hardness may vary in different sections of the pit. However, the modelled mineralization breakage rate was still within the 85th percentile of previous design test data. The only changes made to the plant design was to add an extra secondary crusher per 14 Mtpa module.

- New crusher work index (CWi) tests in 2025 demonstrated a lower range of CWi results between 13.3 and 20.8 kWh/t compared with the average CWi value obtained from historical test work in 1996 of 26.5 kWh/t for the +51 –to 76 mm size fraction.

- Abrasion index (Ai) tests yielded values between 0.26 and 0.40, suggesting relatively high rates of abrasive wear in crushing and grinding circuit operation.

- SMC tests yielded SAG circuit specific energy estimates of 10 to 14 kWh/t.

- These comminution test results would typically be considered indicative of “hard” or “moderately hard” mineralization, within the range expected for this style of mineralization.

- Mineralogical evaluations of multiple mineralized samples concluded that the ratio of chalcopyrite (CuFeS2) to pyrite (FeS2) varied between 1:1 and 2:1. This significantly influenced the maximum copper grade of final concentrate produced, since some pyrite was recovered to concentrate, diluting the chalcopyrite content of concentrate.

- No other base metal sulfides were observed that could result in contamination either of products of the metallurgical process, or of tailings or leach residue streams, supporting production of a clean concentrate.

- Laboratory scale milling and flotation tests determined that copper rougher flotation recovery exceeding 92% can be achieved following a primary grind to 80% passing either 150 or 120 µm to ensure liberation of chalcopyrite and pyrite from each other and from gangue minerals before flotation.

- Flotation procedure and reagent additions initially used for the tests at these grinds were replicated on a series of core samples with copper grades varying between 0.19% and 0.71% Cu. Excellent recoveries were achieved to final cleaner concentrate based on minimum tailings copper grade of around 0.035% indicating average overall copper recovery of 89% for material at the average mineral resource grade of 0.35% around a range of 83 to 95% overall recovery for the lowest to highest grade mineralized samples.

- A rougher concentrate regrind step was incorporated in the tests. Bench scale cleaner flotation tests inclusive of rougher concentrate regrind achieved 20% to 22% Cu in final concentrate.

- The copper flotation tests also demonstrated that between 45% and 70% of molybdenum can be recovered to copper flotation concentrate. Tests to recover Mo from the copper concentrate by a dedicated Mo flotation step followed by cyanide leaching of the concentrate to remove copper have been moderately successful so far but further work is planned to confirm this step in the overall flowsheet.

- Coarse particle flotation (CPF) tests have been completed with the CPF in a flotation pre-concentration role in the milling circuit. Steady state laboratory scale tests were conducted on feed sample containing 0.41% Cu at a target feed size between 150 and 600 µm. Preliminary feed CPF tests have indicated that it may be able to achieve a copper recovery of 94% at 15% mass pull to CPF rougher concentrate, from the 425 x 150µm feed fraction. The concentrate is expected to contain 3 to 5% Cu and would need to be subjected to further regrinding and upgrading in the conventional cleaner flotation circuit. CPF tailings included a relatively barren fraction that could be screened out and routed to final tailings. The preliminary balance indicated that this would amounting to at least 15% of mill feed mass.

- Additional pre-concentration tests of potential mill feed have progressed well in the past few months and final results are now expected around the end of September 2025. Specifically, the following interim results can be reported:

- NextOre conducted a desktop study to assess the heterogeneity of Magnetic Resonance (MR) technology from a Haib core sample database of 242 holes containing 36,867 sample points, composited to intervals of varying length. The study indicated that the Haib deposit exhibits a moderate degree of heterogeneity. In parallel, NextOre confirmed amenability of Cu grade measurement using MR technology, by comparing MR and conventional Cu assay results for a range of mineralization and waste rock drill core samples provided by Koryx. Using the heterogeneity and amenability results, NextOre prepared a simulation demonstrating that 78.9% to 86% of crushed Haib mineralization could potentially be recovered to mill feed using MR bulk rock sorting, containing between 88% and 92.5% of copper contained in ROM material.

- TOMRA have so far completed initial scans of selected sulfide bearing rocks using their laboratory scale XRT sensor. Results indicate that sulfide bearing Haib particles can be clearly differentiated from host rock using XRT sensor technology. The next step in TOMRA’s test program will be small scale laboratory tests to confirm the results of these initial scans.

- Rados has commenced a two-stage evaluation process of their XRF base bulk or particle or sorting technology. First, a portable XRF scanner is currently being used on site to assess amenability of all available core samples to XRF sorting. Rados’s simulation model indicates that bulk rock sorting (at 1000mm) may be able to upgrade ROM material to a grade of about 0.35%Cu @94% Cu recovery, with 20% mass rejection and 0.10%Cu discard grade. The second step has commenced with bulk samples of high grade and low-grade material being compiled by Koryx, for processing using Rados’s laboratory scale sorting unit to confirm the simulation predictions.

- Heavy liquid separation tests of a possible dense medium separation circuit were completed. Although some separation of dense sulfides from lower density gangue minerals was shown to be possible, there as a very high percentage of near density material present, and it was not considered that it would be practicable to operate a DMS circuit successfully. No further DMS test work is planned.

- Column leach tests of high and low-grade samples commenced in June 2025, with the primary objective of demonstrating whether a heap leach process is potentially viable for treatment of lower grade mineralization that cannot be processed profitably through a conventional milling and flotation circuit.

- Bacterial leaching, three different chloride leach processes and a nitrate leach technology are all being tested in these column leach tests. This will be a 6-12month test program, with results by early 2026 expected to be appropriate to support the next level of technical studies.

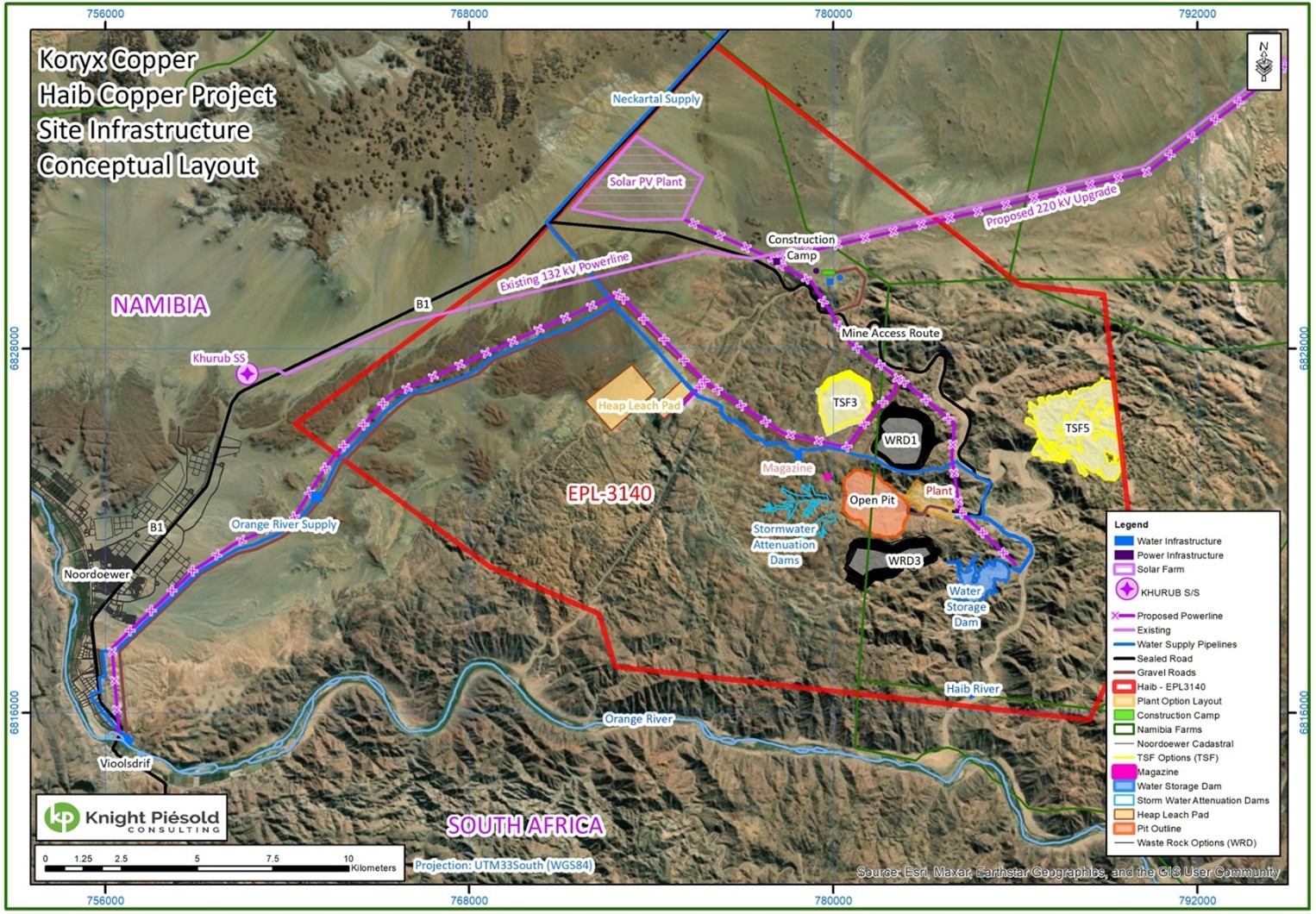

Site Infrastructure

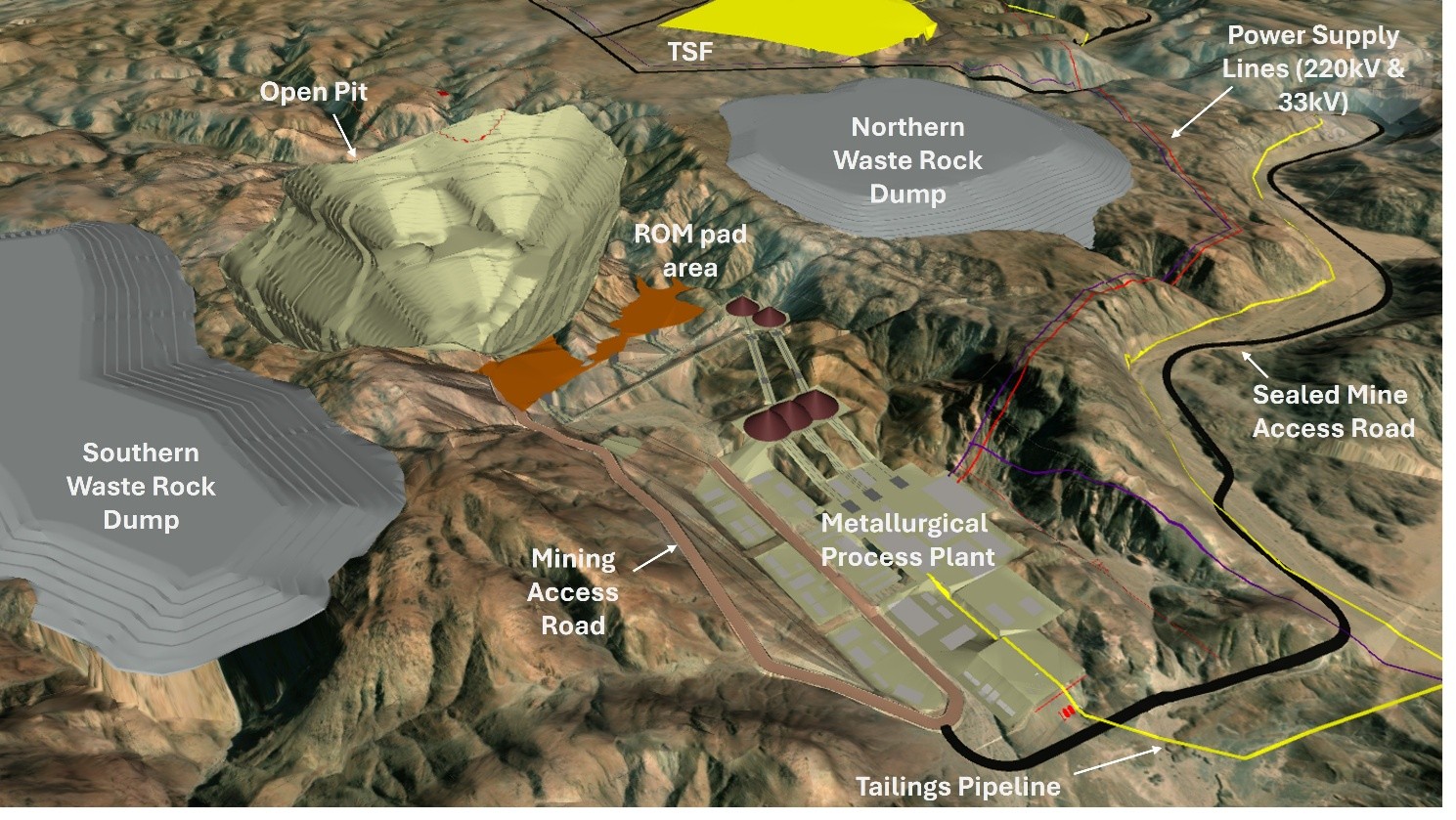

The site layout was updated during the PEA studies, including positioning the metallurgical plant in the optimal position for crushing and feeding rock mined from the pit. The current plant position makes use of the lowest haulage elevation, as well as open flat areas in the downstream part of the Volstruis valley.

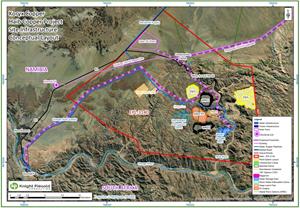

Figure 12: Site Infrastructure Layout

Waste rock dumps were positioned in easily accessible areas to the north and south of the pit using the nearby valley fills, and tailings storage locations are connected to via slurry pipelines from the plant. The project can be accessed via the nearby asphalted B1 highway via a sealed access road which makes use of the shallow gradient created by the Haib River valley.

A water pipeline connects the plant with the abstraction point on the Orange River near to the town of Noordoewer, and powerlines access the plant area from the north where they connect locally with the NamPower 220kV national grid and mine site PV plant in the northwest of the proposed mine licence area.

Process Plant Design

The test work results summarised above as well as the conclusions of several trade-off studies have enabled Koryx and DRA to continue developing the base case process flowsheets for both high grade (HG) and low grade (LG) mineralized material.

The following trade-off studies have been completed by Koryx and its main specialist engineering consultants, specifically Qubeka, DRA and KP:

- A technical evaluation of about thirty metallurgical processes with potential to recover copper present in chalcopyrite concluded that only mineral sorting, coarse particle and conventional flotation and heap leach processes are realistic options for processing of Haib mineralization.

- Comminution test results were used to simulate performance of alternative crushing and milling circuit configurations. For Haib, the optimal configuration was determined to be primary gyratory crushing, secondary cone crushing, tertiary crushing using high pressure grinding rolls (HPGRs) and a single stage of ball milling.

- Cash flow schedules were prepared for several different annual processing rates and cross-over copper grades between high- and low-grade processing. These considered annual revenues, capital and operating costs and electrical power, as well as water requirements and the capacity of largest available crusher units. The optimum combination tested was a 28 Mtpa milling and flotation (MF) concentrator processing material containing > 0.25% Cu and a 7 Mtpa Heap Leach/Solvent Extraction/Copper Electrowinning (HL) circuit processing sulfide material containing between 0.15% and 0.25% Cu as well as oxidised material unresponsive to flotation. The MF plant will produce copper in concentrate, whilst the heap leach circuit will produce copper cathode.

- The latest available estimates of copper recovery as well as operating costs for the open pit and both metallurgical processes were used to re-optimise the pit shell, pushbacks and processing schedules.

- This resulted in a considerable increase in tonnage of material to be processed, with life of mine being extended to 23 years.

- Coarse Particle Flotation (CPF) in the primary milling circuit as tested successfully during this PEA has been included in the base case flowsheet, with target mass rejection of about 20% to coarse tailings in the CPF circuit.

- Following evaluation of completed milling and flotation tests, the primary milling circuit was specified to be able to achieve 80% < 120 µm grind while also being able to operate at 80% < 150 µm. Rougher concentrate will be milled to 80% <25 µm before cleaner flotation.

- A molybdenum flotation circuit has been included in the base case, to recover Mo from copper concentrate. This will be operated in batch mode since it is anticipated that it will be profitable to operate it when pockets of mineralization above average molybdenum content are being mined.

- Four possible hydrometallurgical process routes to recover copper metal from flotation concentrate on site were evaluated. It was concluded that although these are technically feasible, none of them would add value to the project.

- The base case produces copper flotation concentrate to be transported off-site for toll smelting and refining by others, as well as copper cathode metal to be sent directly to market.

- A tailings dewatering trade-off study was completed using multiple specialist consultants. The selected option was thickening of flotation tailings and pumping of the slurry to a conventional tailings storage facility on site.

- Five alternative transport methods and routes for flotation concentrate were considered including Walvis Bay, Lüderitz and Gqeberha (Port Elizabeth) in South Africa. It was concluded that product should be trucked to the nearest port (Lüderitz) for shipping to international smelting facilities.

- Cash flow schedules were prepared for several different annual processing rates and cross-over copper grades between high- and low-grade processing. These considered annual revenues, capital and operating costs and electrical power, as well as water requirements and the capacity of largest available crusher units. The optimum combination tested was a 28 Mtpa milling and flotation (MF) concentrator processing material containing > 0.25% Cu and a 7 Mtpa Heap Leach/Solvent Extraction/Copper Electrowinning (HL) circuit processing sulfide material containing between 0.15% and 0.25% Cu as well as oxidised material

Figure 13: Isometric view of processing plant and mine infrastructure layout

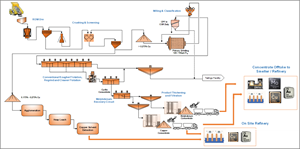

Process Flow Sheet

The base case 28 Mtpa MF flowsheet for the PEA, based on the trade-off outcomes, is highlighted in the Figure below. The proposed flowsheet incorporates the following steps:

- Overall capacity of 28 Mtpa of ROM material is achieved by installing two parallel and identical 14 Mtpa circuits.

- The comminution circuits comprise primary gyratory and secondary cone crushing with a tertiary high pressure grinding roll (“HPGR”) sub-circuit followed by ball milling (HPGR-ball). Three secondary cone crushers per module are likely to be required due to the maximum commercial equipment size that is available.

- The comminution circuits will target a nominal grind of 80% passing 150 µm. The design incorporates sufficient classification and milling power to target a range of 80% passing 120 to 180 µm If the physical characteristics of material received change as the mine plan is developed.

- Coarse particle flotation (CPF) to treat a portion of the mill cyclone underflow for coarse gangue rejection (CGR). The +150 µm fraction of CPF tailings will be screened out and discarded, and CPF concentrate will be reground ahead of conventional cleaner flotation.

- A conventional copper flotation circuit which includes rougher flotation, rougher concentrate re-grind and cleaner flotation for recovery of copper and molybdenum to a bulk copper flotation concentrate.

- A molybdenum recovery circuit which includes a feed dewatering and washing followed by rougher and cleaner flotation with entirely new Mo flotation reagents, to produce molybdenum concentrates and reject copper to Mo flotation tailings. The design also incorporates leaching of the molybdenum concentrate product for removal of residual copper. This circuit will be operated in batch mode since it is anticipated that it will only be profitable to operate it when pockets of higher grade molybdenum mineralization are being mined and processed, or when molybdenum prices increase from current levels.

- A tailings thickening and underflow pumping circuit to transfer thickened wet tailings to the TSF at solids concentration of 55 to 60% w/w.

- Separate concentrate thickening, filtration and product handling facilities for the copper and molybdenum final concentrate products which will be trucked to Lüderitz and shipped to international customers. Pressure filters will be used to reduce moisture content of concentrate filter cake to 10% or less.

Figure 14: Haib Project plant process flowsheet

The heap leach (HL) plant has been sized to process 7 Mtpa of ROM feed to match the steady state mining production rate of 35 Mtpa to be processed in total in the MF and HL plants. This circuit will treat the lower grade sulfide material containing approximately 0.15% to 0.25% Cu and oxides of any grade to produce Grade A copper cathode product (99.995% Cu) that will be trucked, railed and shipped to international customers.

The HL plant flowsheet includes the following features:

- A three-stage crushing, screening, intermediate stockpiling and conveying circuit identical to those of the two MF plant modules, with the capability to process 12 Mtpa if required. This circuit will include a transfer conveyor to enable crushed mineralization to be routed through the MF modules if necessary, to ensure that they can process 14 Mtpa of mineralized material as designed.

- Delivery of low-grade crushed mineralization via the belt conveyor to an agglomeration drum.

- Spreading of agglomerated material with the necessary materials handling to a stable heap leach pad capable of accepting 7 Mtpa of low-grade mineralization. The heap leach pad will include installations to distribute air and leach solution evenly throughout the leach pad and maintain operating temperature within the required temperature range.

- Pregnant leach solution (PLS) and raffinate ponds, and if appropriate on-off pad sections and leach residue (“ripios”) dumps.

- Copper solvent extraction (SX) circuit incorporating extraction, stripping and if necessary washing or scrubbing mixer-settlers.

- Copper raffinate bleed stream, if necessary incorporating a precipitation and liquid/solid separation circuit to remove iron and other dissolved impurities from leach solution in order to facilitate leaching and solvent extraction as well as controlling viscosity of the solution.

- Electrowinning (EW) of copper following SX, including cathode handling and packing prior to loadout of strapped cathode bundles and transport to market.

The heap leach process presented in this PEA Technical Report has primarily been based by Koryx on historical metallurgical test work conducted by previous developers of the project. the design closely follows the conditions and configuration outlined in the 2021 PEA, with additional input and benchmarked information provided by DRA and MJOI. This approach leverages the design parameters established in preceding studies on the Haib Project, pending the completion of additional hydrometallurgical test work currently underway at Mintek under the direction of Koryx and MJOI.

Several copper producers or technology developers have been working on heap leach technology intended specifically for processing of low-grade chalcopyrite mineralization. After consideration of published information, Koryx elected to retain the Mintek Bacterial Heap Leach Process as one of the main options for heap leaching to be tested in 2025. This is the process that was tested in 2020 and included in the 2021 PEA of this Project. The 2020/2021 design and cost estimate basis have been used in this PEA to define the proposed 7 Mtpa heap leach process.

Mintek has done more development work on similar projects since 2020 and Koryx has commissioned additional Haib test work that is currently in process at Mintek, to evaluate potential improvements. Mintek’s process was developed specifically for chalcopyrite mineralization leaching. It has been tested on demonstration plant scale in 20,000 tonne heaps at an Iranian operation. Bacteria capable of operating at different temperature ranges are normally nurtured and then introduced to the heap leach. The process then operates at about 50 ºC and relies partly on heat retention in the heaps by balancing the irrigation and aeration flows to raise and maintain the in-heap temperatures sufficiently to achieve economic chalcopyrite leaching kinetics.

There needs to be enough pyrite in the mineralization to fuel the temperature increase. In addition to heat retention, a practical operation also requires control of heap pH below 2 to 3 and control of the ferric ion concentration of the leach solution to act as an oxidant and sustain bacterial activity. The management of solution flows (switching between raffinate and intermediate leach solution (ILS) for irrigation, and routing drainages to either pregnant or ILS pond), and correct start-up of the heap to initiate bacterial action and heat generation are also important elements of a successful operation.

Another copper project in Namibia has recently reported successful testing of a chloride heap leach process at Mintek. The technical consultant used was MJO Ingeniería y Consultores en Metalurgia (MJOI) based in Santiago, Chile. Koryx has retained MJOI to assist with definition and monitoring of the Haib bacterial leach tests at Mintek and to also specify three different chloride leach column tests at Mintek to be completed in parallel with the bacterial heap leach column test over approximately the next twelve months.

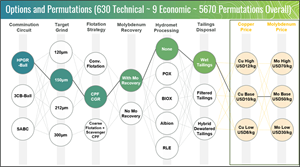

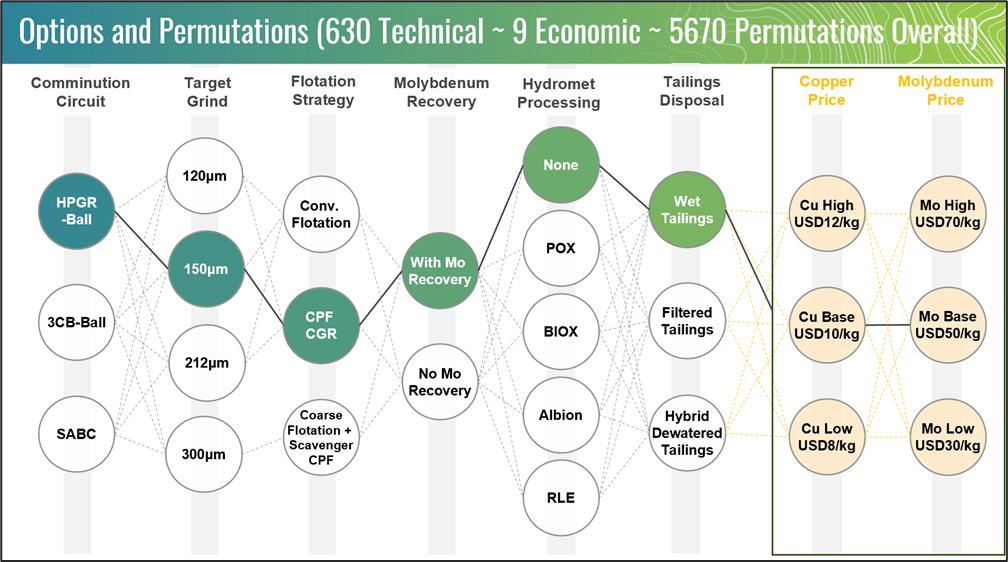

Trade-off Analyses

An overall summary of the options and permutations that were considered for the concentrator PEA flowsheet trade-offs is presented in the Figure below.

Figure 15: Trade-off Analyses Variations Considered

Mine Power Supply

A trade off study was completed to assess different connection and supply alternatives to meet the Project estimated peak power demand of 150 MVA and annual consumption of 1,124 GWh. A hybrid solution combining solar photovoltaic (PV) system and grid supply via the NamPower Harib substation to a new Haib substation was retained for the PEA. The recommended grid supply is to be via a double circuit overhead transmission line (OHTL) configuration for redundancy.

The on-site power infrastructure includes a metering station at the boundary of the mining area to provide NamPower access, while the main substation is located next to the main loads at the processing plant, in the centre of the mine area to reduce energy loss.

It is anticipated that deep connection upgrades will be required on NamPower network upstream of the Harib substation as well as shallow connection upgrades from Harib to the mine site. A grid connection study by NamPower is ongoing to confirm actual upgrades requirements and available preliminary information was used for the PEA. It is assumed that connection will be a Project cost, with the completed infrastructure to be handed back to NamPower.

Alternative energy supply sources were investigated in the trade-off study, including Solar PV and additional battery energy storage system (BESS). These were evaluated for both a 30% and 100% power supply options, subject to regulatory approval. The Namibian Electrical Control Board (ECB) currently allow for up to 30% power supply from alternative source which was retained for the PEA with potential to revisit in future study upgrade. The 30% limit can be increased by application for specific projects, and a 100% potential supply from Solar PV system however provides an important advantage to lower power cost.

Different ownership models were considered including full ownership and purchase agreements with independent power producers (IPP). An IPP purchase agreement was selected for the PEA. On site back up system such as diesel generator at the Haib substation and key areas.

Water supply strategy and off channel storage dam

A water supply alternative assessment was completed to compare various sources of water and considered conveying water from a desalination plant at the coast near Oranjemund, from Naute Dam, from Neckartal Dam and from the nearby Orange River and from local groundwater sources.

Sourcing water from the transboundary Orange River showed as a preferred source of water when combined with off-channel storage to withstand extended periods of droughts and/or low flows in the Orange River and to avoid adverse impacts on downstream users. To meet the Project water demand preliminarily estimated at 20 million cubic metres per annum, abstracting water from the Orange River requires an abstraction weir to be constructed across the river with an intake structure designed to minimise sediment intake. Various possible weir locations were assessed and a site near the town of Noordoewer outside of existing and future water infrastructure was selected as a preferred option. Specialist hydrology and water balancing studies were completed to assess the Orange River yield and release potential through various operating and climatic conditions in order to size the abstraction volumes and that of the off-channel storage for the Project.

The proposed system comprises an abstraction weir, intake structure, a low-lift and two high-lift booster pumping stations, and a steel pipeline delivering water to a terminal reservoir and off-channel storage dam at the mine. This supply system assumes that the pumping scheme will have capacity to abstract and transfer water at higher rates during high flow periods when the Orange River system experiences a surplus, whilst water stored on site will be used when the river experiences lower flows. This requires a sizable off-channel storage dam.

Koryx will continue to assess the water supply options during the PFS studies, including a pipeline connection with the Neckartal Dam 260km to the north for a potential hybrid scheme, allowing water to be sourced from either the river or the dam.

Tailings Facility Options Trade off Study

The Project mining schedule shows that approximately 626 million tonnes of tailings will be generated through the life of mine. A high level siting study and trade off analysis completed by Knight Piésold identified five potential TSF location in the EPL area. The base assumption was to use thickened slurry tailings pumped to the TSF.

The TSF models were compared in terms of embankment construction volumes, footprint area, starter embankment requirements, distance to plant, geotechnical risks, environmental impact, and final height. TSF 5 scored the highest as a most storage effective structure with capacity to store all tailings. The study resulted in TSF 3, close to the Open Pit and northern Waste Rock Dump (WRD), and TSF 5 being retained for the PEA design and cost estimate and can jointly store all tailings storage requirement.

The starter embankments were sized to accommodate approximately 20 months of tailings storage as well as required freeboard for storm events. The embankment comprises an earthfill zone sourced from borrow, filter zone, chimney drain and upstream zone with a lined face tied into the foundation to reduce potential seepage through the dam wall. It is envisaged that the downstream portion of the embankment will be constructed of waste rock. The configuration also includes an underdrainage system and downstream seepage cut off trench to collect and reuse seepage water. TSF 5 embankment is contained within the valley and to be raised downstream for most of its life cycle followed by final centre raises. TSF 3 will use an initial downstream raise, centre raises and a final upstream raise to contain all storage requirement. TSF 5 can store up to 515 million tonnes of tailings, and TSF 3 approximately 110 million tonnes of tailings.

The water management system comprises of a pumping station set on a floating barge linked to a decant causeway. Further trade off studies to consider interim pumping stations in decant towers are also considered for the next design stage. The design basis was developed for the proposed operations using Global Industry Standard on Tailings Management (GISTM) from 2020 to assess the dam classification of the TSF based on the consequence of a hypothetical dam failure.

Mine Access Road

The Project can be accessed from Windhoek or Noordoewer through the B1 National Highway and sets of farm roads and tracks developed during exploration programs. Different access roads were investigated during the conceptual design stage, and the access going along the Haib River bank was rated most favourable in terms of geometrics, gradients, and cut and fill material balance. A key limiting factor from the route going through the plateau is the steep terrain incline, hard rock excavation limiting side hill cuts, and rugged topography to access processing facilities with larger and heavier traffic. However, the route going through the Haib River basin will require further hydrological and engineering mitigation to manage extreme flood events, such as additional fill, river/flood plain crossing/drifts, and sidehill erosion protection/flood mitigation.

Based on the capital cost, maintenance costs, ease of construction, dust mitigation, and visual aesthetics, a sealed road option is recommended for the mine access road for use on all haul vehicles, buses, and general vehicles. A gravel wearing course and dump rock pavement layer with a dust suppressant is recommended for the haul road section between the open pit and processing stockpiles as well as to the waste rock dumps to lower dust emission, wear, and damage to the road surface.

Mine Housing

The conceptual studies developed for the PEA compared different on-site and off-site accommodation packages. On-site accommodation for the Project workforce was selected as the preferred option for the PEA to minimize impacts on the community during construction and operation.

The mining camp and associated infrastructures were placed north of the main mining activities on flatter ground near the Project access road and solar power plant. The design includes workers’ accommodation, multi-purpose warehouses, gravity-fed water and sewer system, power supply and associated infrastructure services to ensure functionality. Prefabricated housing units were used for the preliminary cost estimates with an assumption that the units could be used during operation.

Environmental and Permitting

A comprehensive Environmental and Social Impact Assessment (ESIA) with associated Environmental and Social Management Plan (ESMP) and public consultations is currently being undertaken and developed to both Namibian national requirements and to International Finance Corporation (IFC) standards. The ESIA is being prepared to obtain an Environmental Clearance Certificate (ECC) for the project from Namibian authorities.

The ECC application is planned to be submitted to Namibian authorities in early 2026 once detail from the pre-feasibility study (PFS) level assessments have been included. The Project will be subject to national review and a number of environmental and social conditions stipulating preventative and mitigative measures that will be mandated before the project proceeds.

Baseline studies to support the ESIA process were initiated in 2023 and are ongoing with terrestrial biodiversity, aquatic biodiversity, water resource and water demand impact and archaeological studies near completion and geochemistry, hydrogeology, air quality and background noise well advanced. Additional baseline studies set to commence in September 2025 include a second round of terrestrial biodiversity and socio economics. A routine monitoring program focusing on surface water, groundwater and air is ongoing. Early inputs into defining the biophysical and social baseline were intentional to ensure the facility design process, including trade off studies and concept designs, were informed towards avoidance of potential impacts at early design phase.

The Project initiated stakeholder engagement in 2023 starting with regulators and moving towards broader stakeholders through 2025. These engagements mapped out potential Interested and Affected Persons (I&APs) and commenced with introductory discussions with stakeholders associated with the towns of Noordoewer and Aussenkehr. The regulatory public participation process (PPP), as required by Namibian regulations and IFC performance standards, was initiated in July 2025. Stakeholder perception of the Project at this early stage is generally positive with interest being placed on job creation, broader economic development and opportunity, and community and infrastructure development.

Risks and Opportunities

Opportunities

- Owner mining may improve financial returns compared to Contract Mining.

- Current in-fill and extension drilling is likely to identify additional mineral resources and may also increase average copper grade to be mined and processed.

- Rock sorting tests are in progress. These may enable about 20% of waste rock to be rejected after crushing, with much lower losses of copper. This will increase feed grade to milling and flotation, resulting in greater early and total life of mine cash flow.

- Pre-concentrate from rock sorting will be milled, after which coarse particle flotation can be used to reject additional partially milled barren waste rock and further increase feed grade to flotation.

- The project provides several opportunities to support local and regional socio-economic development in southern Namibia, through job creation, the use and development of local suppliers, the broader multiplier effect and infrastructure development.

- There is an opportunity to increase water recoveries and develop improved TSF stability through better coarse/fines separation and dewatering prior to disposal or at the TSF. This can have a significant impact on construction methodology and possibly on overall water usage and recovery.

Risks

- Further test work may be required to identify how best to remove copper from molybdenum by-product flotation concentrate.

- Access routes to the open pit and process plants could be cut off during exceptional flood events.

- Scale-up of successful bacterial or chloride leach test results may be challenging since the operation must achieve even distribution of leach solution and air to a competently constructed heap leach capable of processing +7 Mtpa of mineralized material at constant temperature throughout the heap.

- Discussions with NamPower on power availability are in progress and NamPower have concluded their review of Koryx grid power supply request. Confirmation of firm grid power availability from ESKOM via NamPower’s interconnection with South Africa is still outstanding,

- The mineralized system contains significant quantities of gangue acid consumers. The operation will need to control acid addition very carefully to avoid uneconomic consumption of fresh sulphuric acid.

- Gangue minerals dissolved in the heap leach will increase the concentration of sulphates in solution. It will be essential to control these concentrations, otherwise this will impede the bioleach or chloride leach processes from dissolving chalcopyrite.

- Geotechnical and hydrogeological uncertainties at the TSF site, including sub-grade terrain challenges, may impact construction and stability. Starter embankment material sources require further investigation.

- The tailings geotechnical parameters (stability, drainage) and geochemical behavior (acid generation potential) are fundamental in the assessment of the dam integrity and groundwater protection. Reasonably conservative assumptions were adopted for the conceptual design but sufficient testwork will be required in the next design stage.

Presentation & Investor Webinar

Koryx Copper will host a live webinar call to discuss the updated PEA report. Participants must register for the event beforehand using the link below.

Date & Time: Friday, September 5, 2025 at 10:00am ET

Registration Link: https://us06web.zoom.us/webinar/register/WN_qUZaHmJdTTyMb21V_tNvlw

Please Join the Koryx management team for the discussion. The webinar will include a formal presentation followed by a Q&A session.

Quality Control

All drill core was logged, photographed, and split with a diamond saw. Half of the core was bagged and sent to ALS Laboratories Ltd. in Johannesburg, South Africa for analysis (SANAS Accredited Testing Laboratory, No. T0387) and ActLabs in Canada, while the other half was quartered with one quarter archived and stored on site for verification and reference purposes while the other quarter will be used for metallurgical test work. 33 elements are analyzed by Induced Coupled Plasma (ICP) utilizing a 4-acid digestion and gold is assayed for using a 30g fire assay method. Duplicate samples, blanks, and certified standards are included with every batch and are actively used to ensure proper quality assurance and quality control (“QA/QC”) The QA/QC frequency is 1 in 20 for each of blanks, duplicates and standards.

Qualified Persons

The Qualified Person for the Mineral Resource estimate is Mr. Jeremy C. Witley (BSc Hons, MSc (Eng.)) and he has reviewed and approved the scientific and technical information in this news release. Mr. Witley is a geologist with more than 35 years’ experience in base and precious metals exploration and mining as well as mineral resource evaluation and reporting. He is Head of Mineral Resources for The MSA Group, is independent of the Company and its mineral properties (an independent consulting company), is registered with the South African Council for Natural Scientific Professions (SACNASP) and is a Fellow of the Geological Society of South Africa (GSSA). Mr. Witley has the appropriate relevant qualifications and experience to be considered a “Qualified Person” for the style and type of mineralization and activity being undertaken as defined in National Instrument 43-101 Standards of Disclosure of Mineral Projects.

Mr. Werner Moeller is a Director and Principal Mining Engineering Consultant of Qubeka Mining Consultants CC based in Windhoek, Namibia and has reviewed and approved the scientific and technical information in this news release. He holds a BEng degree in Mining Engineering and a BEng (Hons) degree in Industrial Engineering from the University of Pretoria (South Africa). He is a Fellow of the Australian Institute of Mining and Metallurgy (membership number 329888) and a Member of the South African Institute of Mining and Metallurgy (membership number 704793). Mr. Moeller has been practicing his profession continuously since 2002 and has 22 years of mine planning and operations experience across a range of African projects. Mr. Moeller is independent of the Company and its mineral properties and is a Qualified Person for the purposes of National Instrument 43-101.

About Koryx Copper Inc.

Koryx Copper Inc. is a Canadian copper development Company focused on advancing the 100% owned Haib Copper Project in Namibia whilst also building a portfolio of copper exploration licenses in Zambia. Haib is a large, advanced (PEA-stage) copper/molybdenum porphyry deposit in southern Namibia with a long history of exploration and project development by multiple operators. More than 80,000m of drilling has been conducted at Haib since the 1970’s with significant exploration programs led by companies including Falconbridge (1964), Rio Tinto (1975) and Teck (2014). Extensive metallurgical testing and various technical studies have also been completed at Haib to date.

Additional studies are underway aiming to demonstrate Haib as a future long-life, low-cost, low-risk open pit, sulfide flotation copper project with the potential for additional copper production from heap leaching. Haib has a current mineral resource of 414Mt @ 0.35% Cu for 1,459Mt of contained copper in the Indicated category and 345Mt @ 0.33% Cu for 1136Mt of contained copper in the Inferred category (0.25% Cu cut-off).

Mineralization at Haib is typical of a porphyry copper deposit and it is one of only a few examples of a Paleoproterozoic porphyry copper deposit in the world and one of only two in southern Africa (both in Namibia). Due to its age, the deposit has been subjected to multiple metamorphic and deformation events but still retains many of the classic mineralization and alteration features typical of these deposits. The mineralization is dominantly chalcopyrite with minor bornite and chalcocite present and only minor secondary copper minerals at surface due to the arid environment.

Further details of the Haib Copper Project are available in the corresponding technical report titled, "NI 43-101 Technical Report – August 2024 Mineral Resource Estimate for the Haib Copper Project, Namibia" dated effective August 31, 2024 (the "Technical Report"). The Technical Report and other information is available on the Company's website at https://koryxcopper.com and under the Company's profile on SEDAR+ at www.sedarplus.ca.

ON BEHALF OF THE BOARD OF DIRECTORS

"Heye Daun"

President, CEO and Director

Additional information is also available by contacting the Company:

Julia Becker

Corporate Communications

jbecker@koryxcopper.com

+1-604-785-0850

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Statement Regarding Forward-Looking Information

This press release contains "forward-looking information" within the meaning of applicable Canadian securities legislation. Forward-looking information includes, without limitation, statements regarding the use of proceeds from the Company's recently completed financings and the future or prospects of the Company. Generally, forward-looking information can be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect ", "is expected ", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur" or "be achieved". Forward-looking statements are necessarily based upon a number of assumptions that, while considered reasonable by management, are inherently subject to business, market, and economic risks, uncertainties, and contingencies that may cause actual results, performance, or achievements to be materially different from those expressed or implied by forward-looking statements. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, other factors may cause results not to be as anticipated, estimated, or intended. There can be no assurance that such information will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking information. Other factors which could materially affect such forward-looking information are described in the risk factors in the Company's most recent annual management discussion and analysis. The Company does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

Images accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/d53f4ddb-d66d-4da9-a03b-bb8b2d4cb234

https://www.globenewswire.com/NewsRoom/AttachmentNg/a1f909f4-c19c-40c4-a890-f45a73f0cc05

https://www.globenewswire.com/NewsRoom/AttachmentNg/51557f98-7934-497f-8845-2c310ab22a7d

https://www.globenewswire.com/NewsRoom/AttachmentNg/8dc0d991-f300-4078-9f87-304b0e084dfc

https://www.globenewswire.com/NewsRoom/AttachmentNg/f0d25e2e-8823-4b8c-9cf4-057fbefbabe3

https://www.globenewswire.com/NewsRoom/AttachmentNg/7fd99f3d-517d-4666-90b8-14a38cf8237e

https://www.globenewswire.com/NewsRoom/AttachmentNg/e95cf074-9319-42e4-a84c-71320e112fdb

https://www.globenewswire.com/NewsRoom/AttachmentNg/8d2c228e-3e06-4bc2-bd46-fe20131e5587